Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

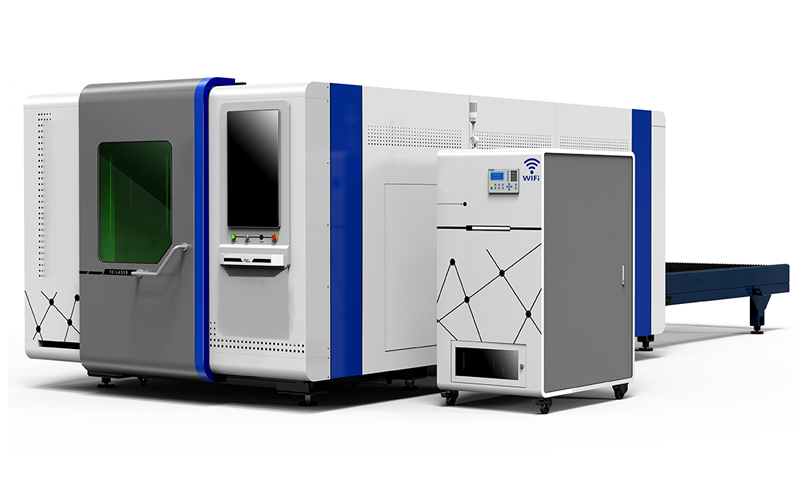

6KW large surround fiber laser cutting machine: industrial-grade efficient and precise cutting solution

Product Overview - Why choose 6KW large surround fiber laser cutting machine?

Our 6KW large surround fiber laser cutting machine is a high-end equipment designed for industrial-grade sheet metal processing. It uses MAX fiber laser, which has strong power and long life (100,000 hours+). It can achieve efficient cutting of 1-40mm carbon steel, 1-25mm stainless steel, and 1-16mm aluminum plates. It is widely used in automobile manufacturing, engineering machinery, shipbuilding and other industries.

✔ Ultra-high power 6KW: Cutting efficiency of thick plates increased by 50%

✔ Fully enclosed protective cover + dust removal system: safer and more environmentally friendly working environment

✔ Intelligent CNC system: Bochu/PA CNC, accuracy ±0.05mm

✔ Automatic loading and unloading (optional): unmanned production, 24-hour continuous operation

Core technology innovations of the fiber laser cutting machine

1. 6KW high-power fiber laser

MAX/Raycus laser source (optional), photoelectric conversion rate> 30%, 60% more energy-saving than traditional CO₂ laser

Can cut 40mm carbon steel, 25mm stainless steel, 16mm aluminum plate, to meet the needs of heavy sheet metal

Pulse/continuous mode switching, adapt to different materials

2. Large surround fully enclosed structure of the fiber laser machine

360° protective cover to prevent laser overflow, in line with international safety standards (CE/ISO certification)

Efficient dust removal system (optional) to reduce metal dust pollution

3. High-precision CNC system

Bochu FSCUT professional cutting system

AI intelligent optimization path, reduce idle time, improve cutting efficiency by 20%

Support CAD/CAM import, one-click generation of complex graphics processing code

4. Heavy machine tool structure + high dynamic performance

Welding frame + gantry structure, stronger rigidity, reduced vibration

Linear motor/servo drive (optional), maximum no-load speed 130m/min, acceleration 1.5G

5. Intelligent auxiliary system (optional)

Automatic focusing laser head: real-time adaptation to different material thicknesses

Automatic loading and unloading system: 24-hour unmanned production

Remote monitoring: real-time viewing of production status via mobile phone/computer

Technical Parameters of the fiber laser cutting machine

Model | Fiber laser cutting machine |

Working Area | 1500*3000mm |

Laser Power | 6kw |

Laser Generator | Max |

Laser Wave Length | 1064nm |

Working Table | Sawtooth-table |

Maximum Idle Running Speed | 140m/min |

Maximum acceleration | 1.2G |

Position Accuracy | ±0.03mm/m |

Repeat Positional Accuracy | ± 0.02mm |

Control System | PC control with CYPCUT |

Position Type | red dot |

Power Consumption | ≤24KW |

Working Voltage | 380V ±10 % 50/60Hz |

Auxiliary Gas | oxygen,nitrogen,air |

Working life of fiber module | More than 100000 hours |

Fiber laser cutting head | BLT421 Auto focus laser cutting head |

Cooling System | Hanli industrial water chiller |

Work Environment | 0-45°C, Moisture 45-85% |

Delivery time | 25 working days |

Customer Benefits - What can you get by choosing our 6KW laser cutting machine?

Customer Benefits - What can you get by choosing our 6KW laser cutting machine?

1. Cost reduction and efficiency improvement - compared with plasma cutting, it saves 50% of energy consumption and increases efficiency by 3 times

2. High-quality cutting - no burrs, no deformation, and eliminates secondary processing

3. Intelligent production - can be matched with automated production lines to reduce labor costs

4. Long-term stability - MAX/Raycus laser, 100,000 hours of ultra-long service life

5. Environmental protection and safety - fully enclosed design + dust removal system, in line with international environmental standards

6KW large surround fiber laser cutting machine: industrial-grade efficient and precise cutting solution

Product Overview - Why choose 6KW large surround fiber laser cutting machine?

Our 6KW large surround fiber laser cutting machine is a high-end equipment designed for industrial-grade sheet metal processing. It uses MAX fiber laser, which has strong power and long life (100,000 hours+). It can achieve efficient cutting of 1-40mm carbon steel, 1-25mm stainless steel, and 1-16mm aluminum plates. It is widely used in automobile manufacturing, engineering machinery, shipbuilding and other industries.

✔ Ultra-high power 6KW: Cutting efficiency of thick plates increased by 50%

✔ Fully enclosed protective cover + dust removal system: safer and more environmentally friendly working environment

✔ Intelligent CNC system: Bochu/PA CNC, accuracy ±0.05mm

✔ Automatic loading and unloading (optional): unmanned production, 24-hour continuous operation

Core technology innovations of the fiber laser cutting machine

1. 6KW high-power fiber laser

MAX/Raycus laser source (optional), photoelectric conversion rate> 30%, 60% more energy-saving than traditional CO₂ laser

Can cut 40mm carbon steel, 25mm stainless steel, 16mm aluminum plate, to meet the needs of heavy sheet metal

Pulse/continuous mode switching, adapt to different materials

2. Large surround fully enclosed structure of the fiber laser machine

360° protective cover to prevent laser overflow, in line with international safety standards (CE/ISO certification)

Efficient dust removal system (optional) to reduce metal dust pollution

3. High-precision CNC system

Bochu FSCUT professional cutting system

AI intelligent optimization path, reduce idle time, improve cutting efficiency by 20%

Support CAD/CAM import, one-click generation of complex graphics processing code

4. Heavy machine tool structure + high dynamic performance

Welding frame + gantry structure, stronger rigidity, reduced vibration

Linear motor/servo drive (optional), maximum no-load speed 130m/min, acceleration 1.5G

5. Intelligent auxiliary system (optional)

Automatic focusing laser head: real-time adaptation to different material thicknesses

Automatic loading and unloading system: 24-hour unmanned production

Remote monitoring: real-time viewing of production status via mobile phone/computer

Technical Parameters of the fiber laser cutting machine

Model | Fiber laser cutting machine |

Working Area | 1500*3000mm |

Laser Power | 6kw |

Laser Generator | Max |

Laser Wave Length | 1064nm |

Working Table | Sawtooth-table |

Maximum Idle Running Speed | 140m/min |

Maximum acceleration | 1.2G |

Position Accuracy | ±0.03mm/m |

Repeat Positional Accuracy | ± 0.02mm |

Control System | PC control with CYPCUT |

Position Type | red dot |

Power Consumption | ≤24KW |

Working Voltage | 380V ±10 % 50/60Hz |

Auxiliary Gas | oxygen,nitrogen,air |

Working life of fiber module | More than 100000 hours |

Fiber laser cutting head | BLT421 Auto focus laser cutting head |

Cooling System | Hanli industrial water chiller |

Work Environment | 0-45°C, Moisture 45-85% |

Delivery time | 25 working days |

Customer Benefits - What can you get by choosing our 6KW laser cutting machine?

Customer Benefits - What can you get by choosing our 6KW laser cutting machine?

1. Cost reduction and efficiency improvement - compared with plasma cutting, it saves 50% of energy consumption and increases efficiency by 3 times

2. High-quality cutting - no burrs, no deformation, and eliminates secondary processing

3. Intelligent production - can be matched with automated production lines to reduce labor costs

4. Long-term stability - MAX/Raycus laser, 100,000 hours of ultra-long service life

5. Environmental protection and safety - fully enclosed design + dust removal system, in line with international environmental standards

content is empty!