Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-06-10 Origin: Site

The Application of Laser Cutting Technology in Agricultural Machinery Manufacturing

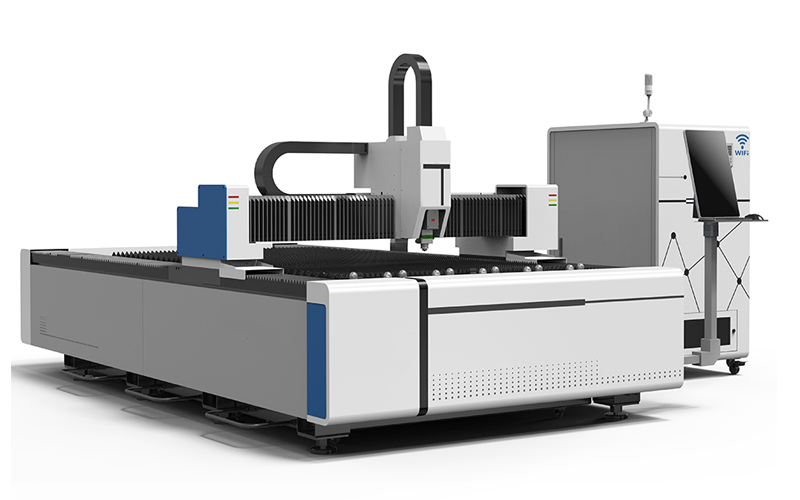

Introduction of the fiber laser cutting machine:

The agricultural machinery industry demands high precision, efficiency, and durability in equipment manufacturing. Traditional cutting methods like plasma, oxy-fuel, or mechanical shearing often struggle to meet these requirements. Laser cutting technology, however, offers unmatched speed, accuracy, and versatility, making it an ideal solution for producing high-quality farm machinery components.

Why Fiber Laser Cutting is Transforming Agricultural Equipment?

1. Unmatched Precision & Complex Designs

Laser cutting uses a high-energy laser beam to cut metals with micron-level accuracy. This precision is crucial for manufacturing:

Combine harvester blades – Ensures optimal cutting performance

Tractor chassis & frames – Enhances structural integrity

Seeders & planters – Delivers consistent hole patterns for precise seed placement

Unlike traditional methods, lasers handle intricate shapes (e.g., ventilation holes in grain dryers) without extra tooling costs.

2. Faster Production with Minimal Waste

High-speed cutting reduces production time (up to 3x faster than plasma).

Nesting software maximizes material usage, lowering scrap costs for large-scale manufacturing.

Thinner heat-affected zones (HAZ) reduce warping, saving post-processing time.

3. Material Versatility for Robust Equipment

Modern laser cutters work with various metals, including:

Stainless steel – For corrosion-resistant parts (e.g., sprayer tanks)

Hardox® steel – Used in plowshares & tillage tools

Aluminum – Lightweight yet durable for tractor cabs & storage bins

4. Cost Efficiency in Mass Production

No physical tool wear → Lower maintenance costs

Automated cutting reduces labor dependency

Lower energy consumption compared to plasma cutting

Real-World Applications in Agri-Machinery

Combine Harvesters – Laser-cut blades, sieves & augers resist wear while improving grain separation.

Seed Drills & Planters – Precision-cut disc openers & seed tubes ensure uniform sowing depth.

Irrigation Systems – Laser-perforated pipes & nozzles for optimized water flow.

Tractor Components – Structural parts (frames, brackets, cabins) benefit from burr-free edges, reducing assembly time.

Future Trends: Smart Farming & Laser Tech

With the rise of automated agriculture, laser-cut sensors and IoT-compatible parts will enable self-adjusting machinery. Fiber lasers are also evolving to cut thicker materials (up to 30mm steel), further expanding their role in heavy-duty farm equipment.

Conclusion

Laser cutting is revolutionizing agri-machinery by delivering faster, cleaner, and more durable components. Manufacturers adopting this tech gain a competitive edge—producing high-performance equipment that meets modern farming demands.

content is empty!

content is empty!