Please Choose Your Language

The Ultimate Hybrid Laser Cutting Solution

The 6000W 5-Axis Sheet & Tube Laser Cutting Machine represents a revolutionary leap in industrial fabrication. Designed for manufacturers who demand precision, efficiency, and versatility, this hybrid system eliminates the need for separate sheet and tube cutting machines. Whether you're working with structural steel, automotive parts, HVAC components, or architectural metalwork, this machine delivers flawless accuracy, high-speed cutting, and superior automation capabilities.

Unmatched Cutting Power & Performance

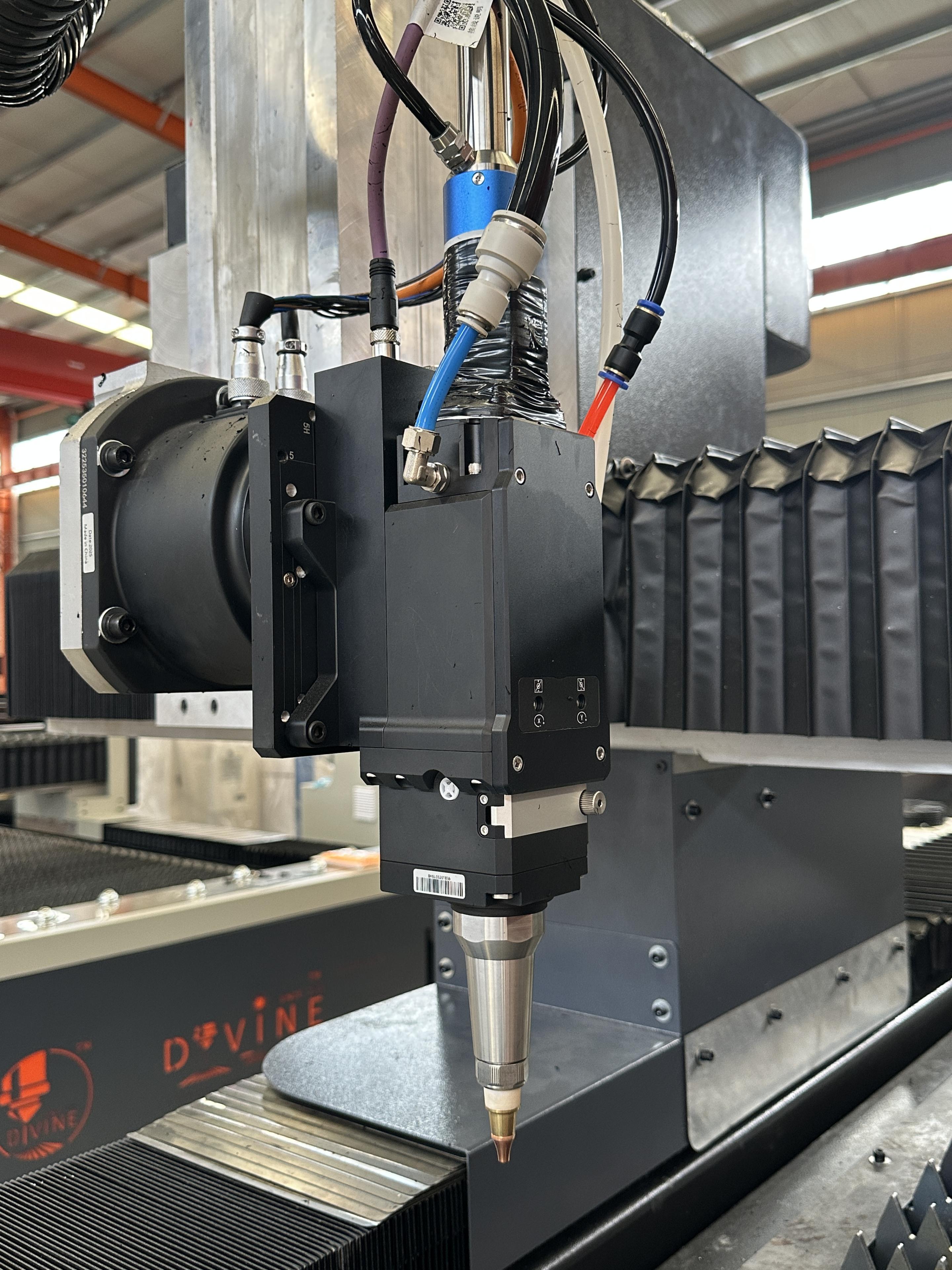

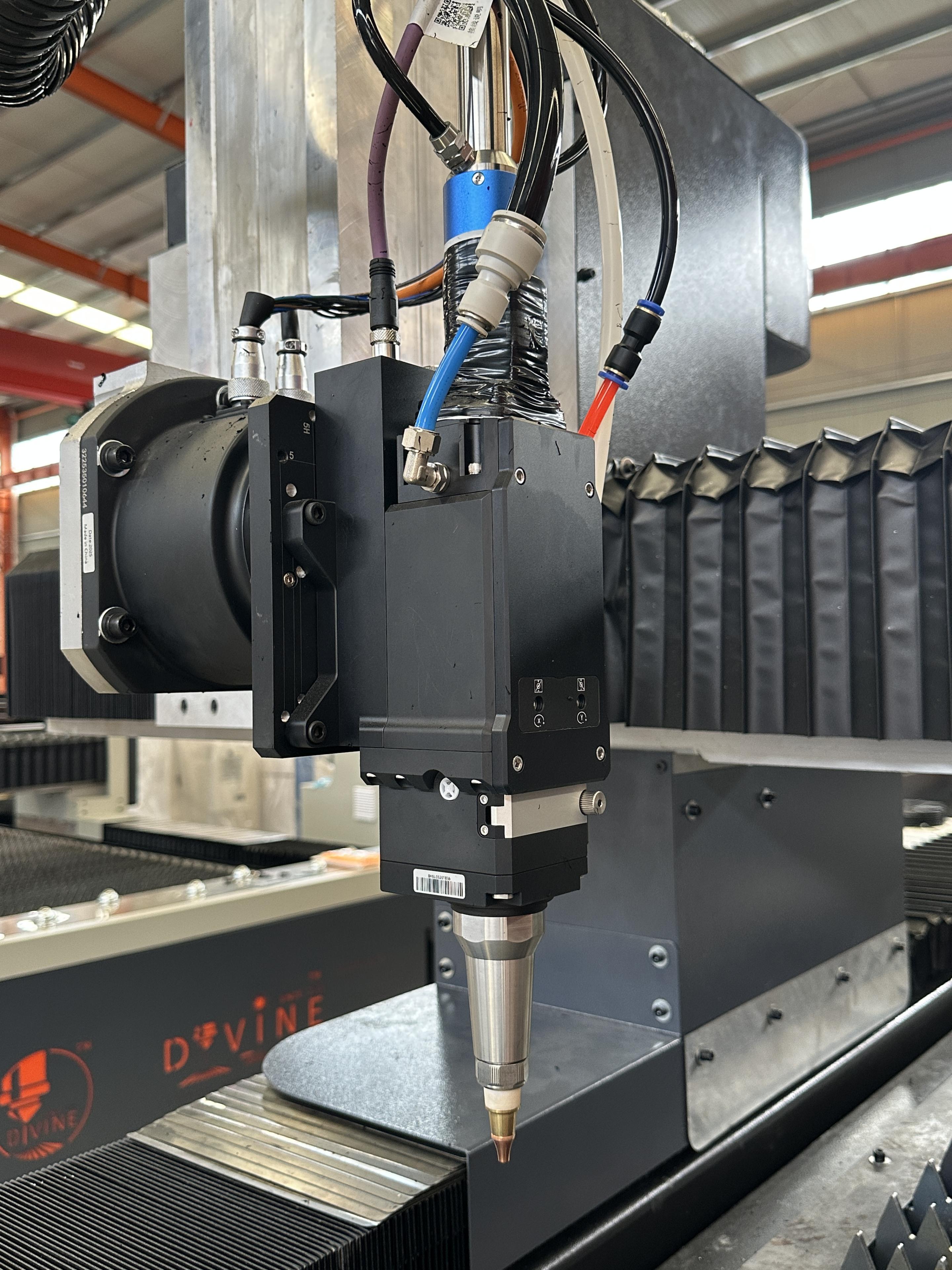

Powered by a 6000W fiber laser (with adjustable settings from 2000W to 6000W), this machine offers up to 50% faster cutting speeds compared to traditional CO₂ lasers. The true 5-axis cutting head (±135° bevel cutting) enables complex angular cuts without repositioning, drastically reducing processing time. With positioning accuracy of ±0.03mm/m and cut quality tolerance of ±0.05mm, even the most intricate designs are executed flawlessly.

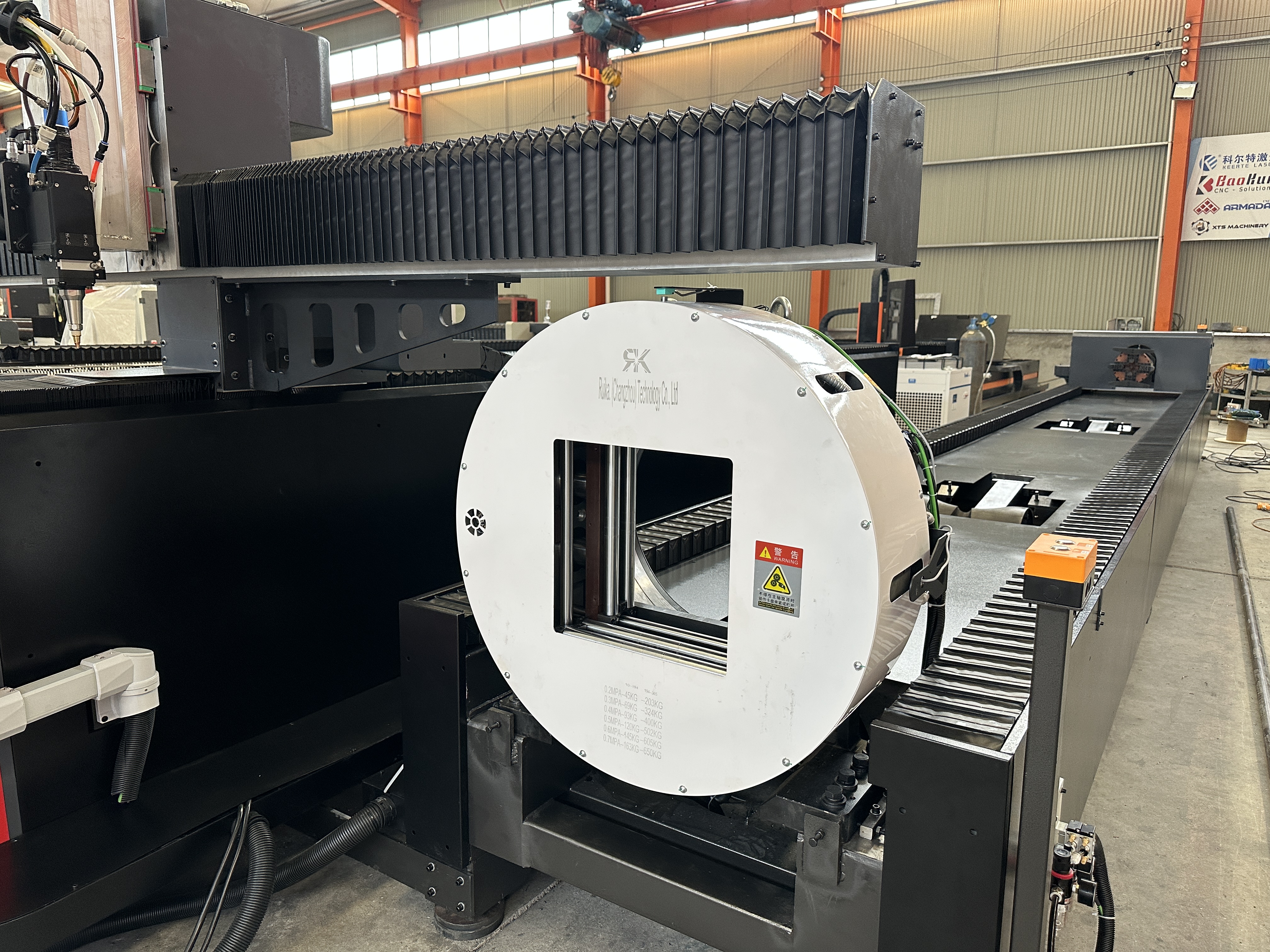

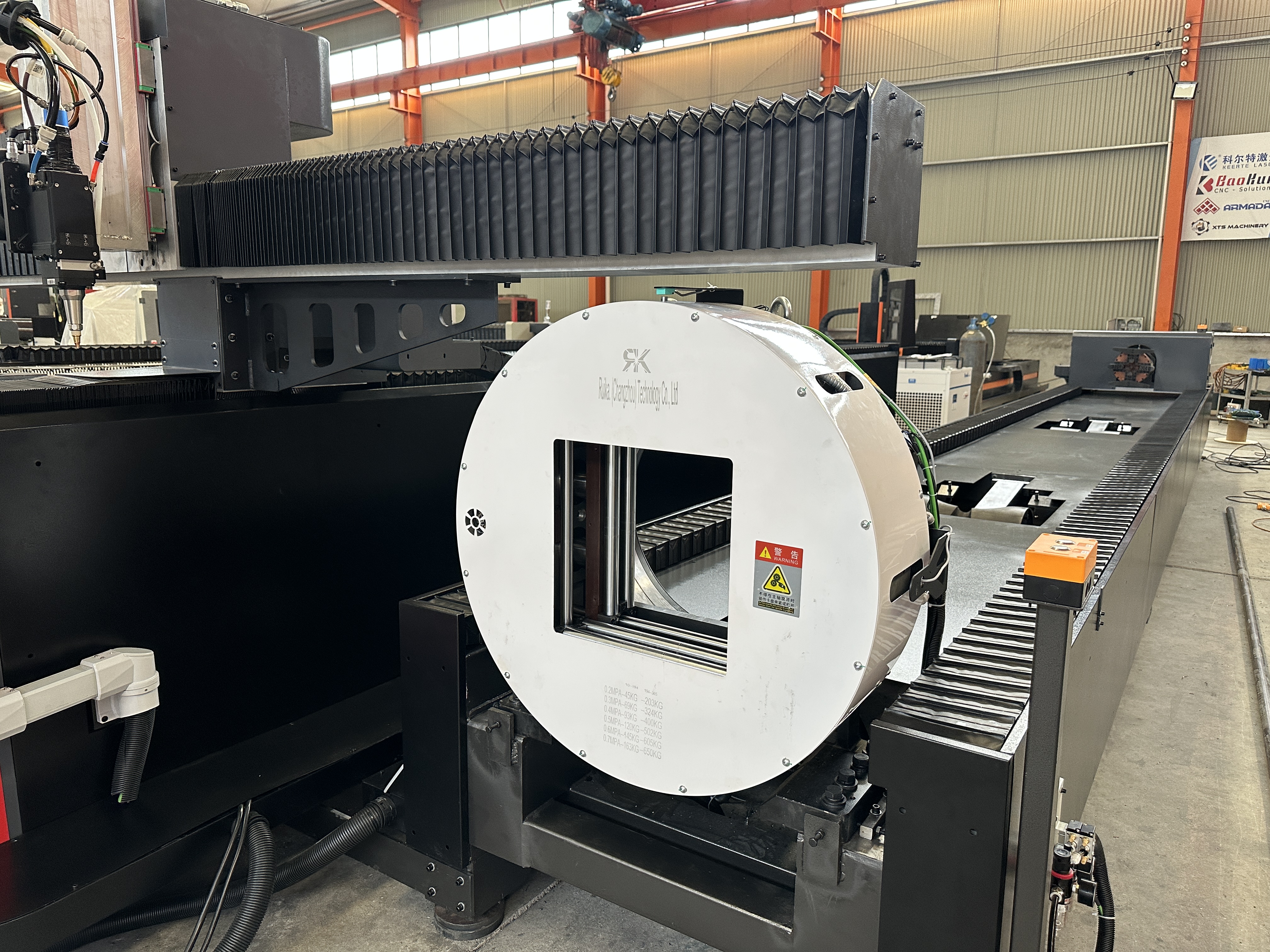

The cutting bed supports 2000mm × 4000mm sheets, while the 350mm chuck accommodates tubes up to Ø350mm × 7500mm. Heavy-duty rollers and HIWIN linear guides ensure smooth material handling, minimizing deflection even with large-diameter pipes and structural beams.

Seamless Hybrid Cutting for Sheet & Tube in One Fiber Laser Cutting Machine

1.Unlike conventional systems that require separate setups for sheet and tube cutting, this all-in-one solution optimizes workflow efficiency. Switch seamlessly between flat sheets and round/square/rectangular tubes without downtime. Automated loading options (conveyor belts for sheets, tube feeders) allow unattended production, significantly reducing labor costs.

2.With software, intelligent nesting maximizes material yield (30-50% less waste), while AI-optimized cutting paths minimize operation time. Remote monitoring capabilities (IoT-ready) ensure real-time performance tracking and predictive maintenance.

3.Engineered for Heavy-Duty Industrial Applications

Built with Japanese Yaskawa servo motors and Taiwan HIWIN linear guides, the machine guarantees long-term stability even under 24/7 production. The high-rigidity frame minimizes vibration, ensuring consistent cuts on materials ranging from 0.5mm-thin stainless steel to 50mm-thick carbon steel.

Fiber Laser cutting machine ---Key industries benefiting from this system include:

Construction & Structural Steel (beams, frames, columns)

Automotive & Aerospace (chassis parts, exhaust pipes)

Shipbuilding & Heavy Machinery (plate cutting, pipe bending prep)

HVAC & Industrial Piping (ductwork, fittings)

Fiber Laser Cutting Machine---Long-Term Cost Savings & ROI Benefits

✅ Lower Operating Costs – Fiber laser consumes 30% less power vs. CO₂ lasers

✅ Minimal Maintenance – Consumables last 3x longer, reducing downtime

✅ Automated Production – Supports lights-out manufacturing for overnight runs

✅ Material Optimization – Intelligent nesting cuts waste by up to 50%

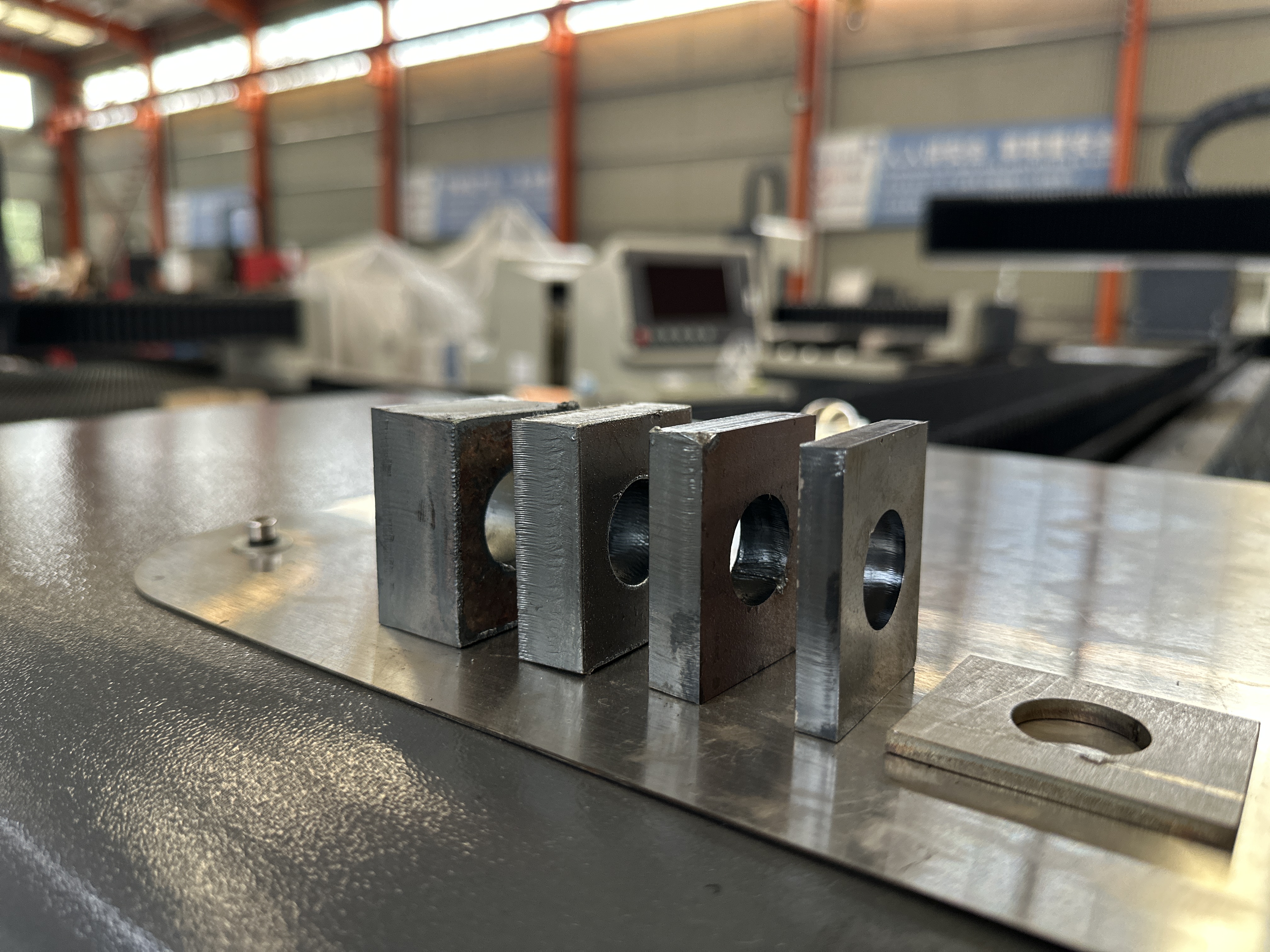

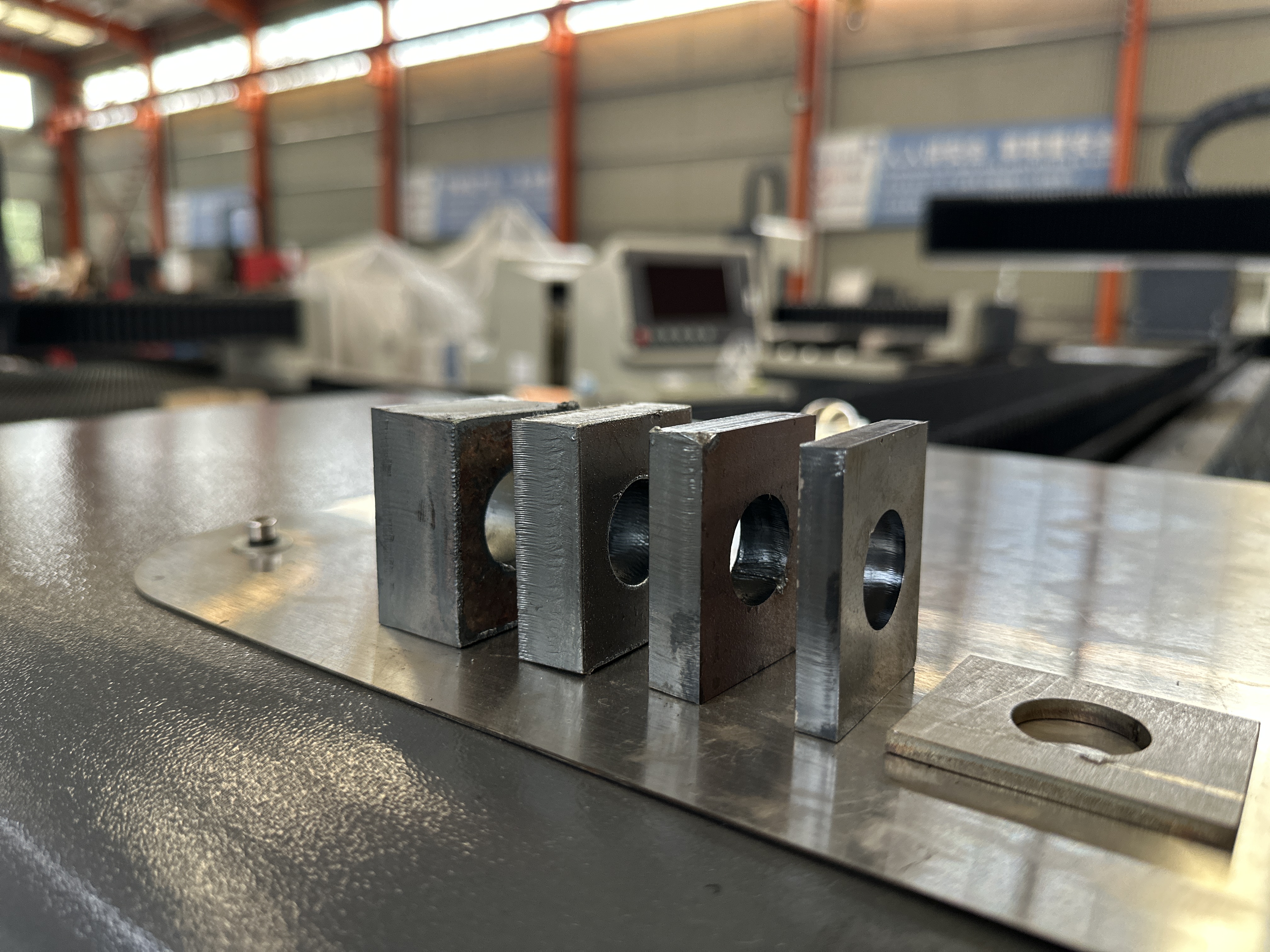

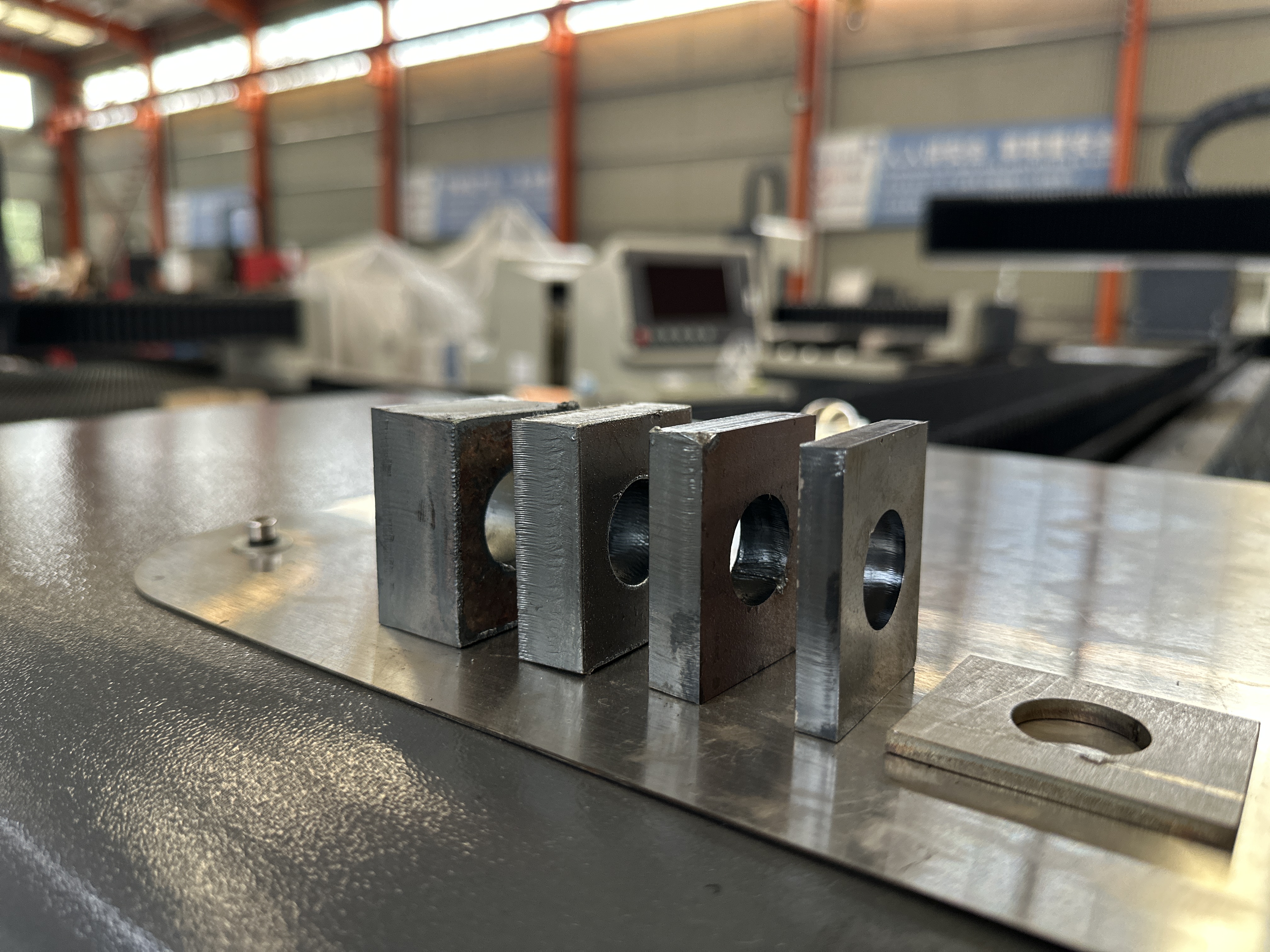

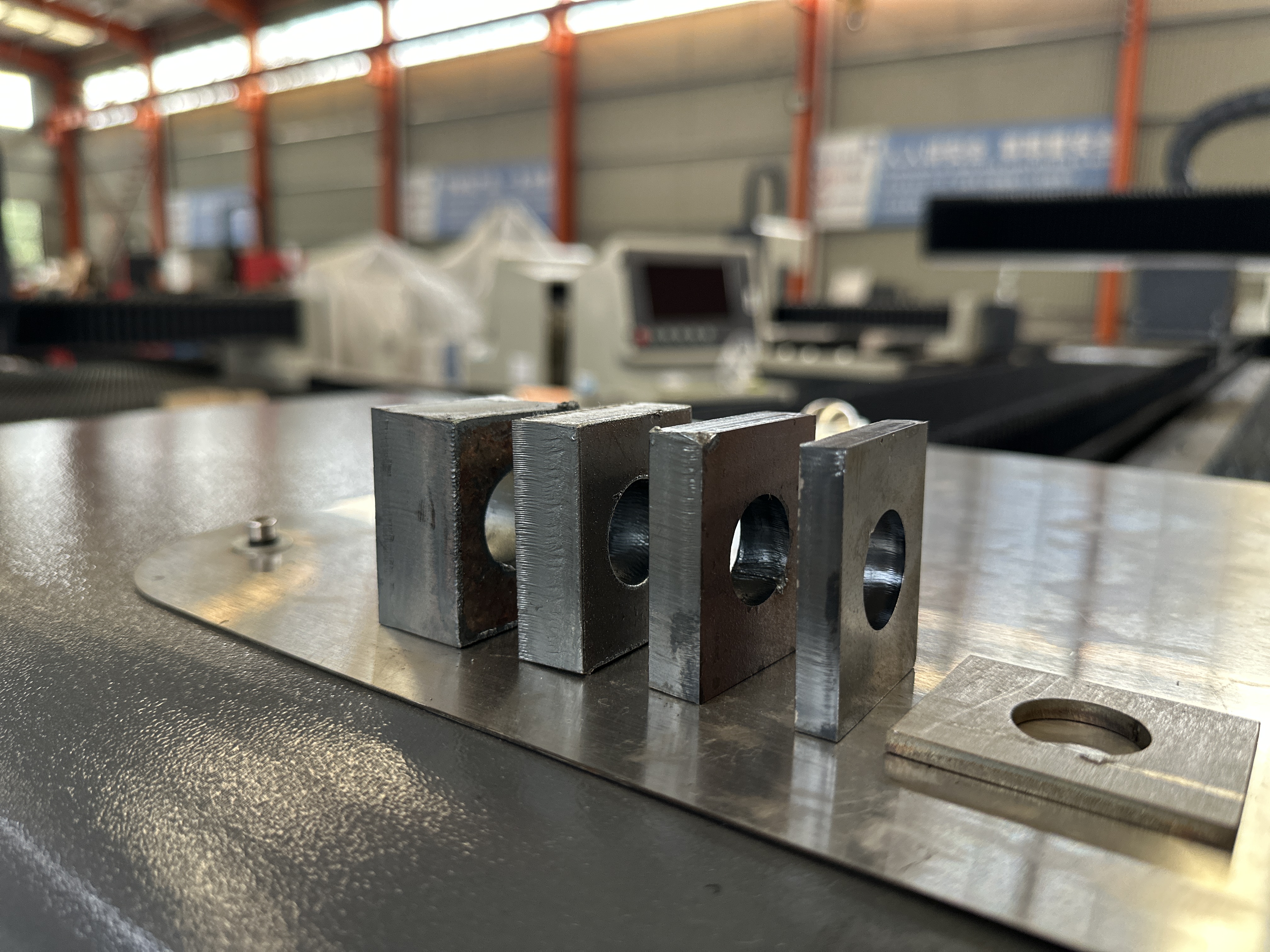

Fiber Laser cutting machine details display:

The Ultimate Hybrid Laser Cutting Solution

The 6000W 5-Axis Sheet & Tube Laser Cutting Machine represents a revolutionary leap in industrial fabrication. Designed for manufacturers who demand precision, efficiency, and versatility, this hybrid system eliminates the need for separate sheet and tube cutting machines. Whether you're working with structural steel, automotive parts, HVAC components, or architectural metalwork, this machine delivers flawless accuracy, high-speed cutting, and superior automation capabilities.

Unmatched Cutting Power & Performance

Powered by a 6000W fiber laser (with adjustable settings from 2000W to 6000W), this machine offers up to 50% faster cutting speeds compared to traditional CO₂ lasers. The true 5-axis cutting head (±135° bevel cutting) enables complex angular cuts without repositioning, drastically reducing processing time. With positioning accuracy of ±0.03mm/m and cut quality tolerance of ±0.05mm, even the most intricate designs are executed flawlessly.

The cutting bed supports 2000mm × 4000mm sheets, while the 350mm chuck accommodates tubes up to Ø350mm × 7500mm. Heavy-duty rollers and HIWIN linear guides ensure smooth material handling, minimizing deflection even with large-diameter pipes and structural beams.

Seamless Hybrid Cutting for Sheet & Tube in One Fiber Laser Cutting Machine

1.Unlike conventional systems that require separate setups for sheet and tube cutting, this all-in-one solution optimizes workflow efficiency. Switch seamlessly between flat sheets and round/square/rectangular tubes without downtime. Automated loading options (conveyor belts for sheets, tube feeders) allow unattended production, significantly reducing labor costs.

2.With software, intelligent nesting maximizes material yield (30-50% less waste), while AI-optimized cutting paths minimize operation time. Remote monitoring capabilities (IoT-ready) ensure real-time performance tracking and predictive maintenance.

3.Engineered for Heavy-Duty Industrial Applications

Built with Japanese Yaskawa servo motors and Taiwan HIWIN linear guides, the machine guarantees long-term stability even under 24/7 production. The high-rigidity frame minimizes vibration, ensuring consistent cuts on materials ranging from 0.5mm-thin stainless steel to 50mm-thick carbon steel.

Fiber Laser cutting machine ---Key industries benefiting from this system include:

Construction & Structural Steel (beams, frames, columns)

Automotive & Aerospace (chassis parts, exhaust pipes)

Shipbuilding & Heavy Machinery (plate cutting, pipe bending prep)

HVAC & Industrial Piping (ductwork, fittings)

Fiber Laser Cutting Machine---Long-Term Cost Savings & ROI Benefits

✅ Lower Operating Costs – Fiber laser consumes 30% less power vs. CO₂ lasers

✅ Minimal Maintenance – Consumables last 3x longer, reducing downtime

✅ Automated Production – Supports lights-out manufacturing for overnight runs

✅ Material Optimization – Intelligent nesting cuts waste by up to 50%

Fiber Laser cutting machine details display:

content is empty!