Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-02 Origin: Site

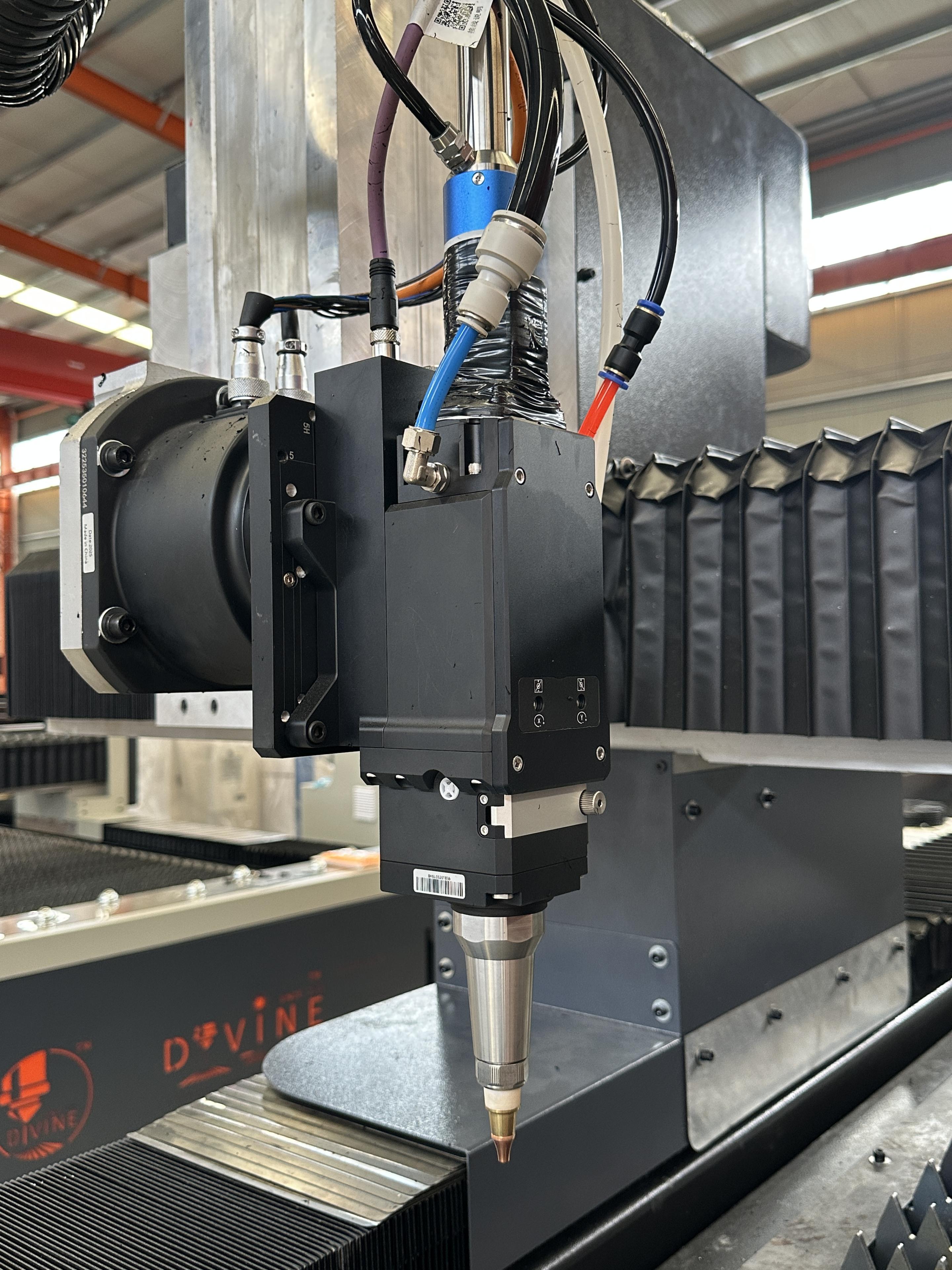

Five-Axis Laser Processing Technology: Leading a Precision Revolution in Mold Manufacturing

In high-end manufacturing, five-axis linkage technology has long been a core process in the aerospace industry due to its superior flexibility and precision, widely used in the precision milling of impellers, blades, and complex structural components. Now, this technology is entering the mold manufacturing industry in a new guise, especially when combined with high-energy laser processing, bringing unprecedented breakthroughs in efficiency and quality.

1.Five-Axis Laser Processing: Reshaping the New Standard for Efficient and Precision Laser Cutting

Laser cutting is one of the most advanced sheet metal forming technologies currently available. With its ultra-high precision, non-contact processing, and extremely fast cutting speed, it is considered a crucial process to replace traditional stamping forming in the future. The introduction of five-axis laser technology has greatly expanded its capabilities—not only can it handle the processing challenges of complex three-dimensional molds, but it can also significantly optimize production efficiency and cost control.

2.The Core Principle of Laser Cutting machine

Laser cutting relies on focusing a high-energy beam to bring the material to a molten or vaporized state in a very short time. Then, a high-pressure auxiliary gas (oxygen or nitrogen) is used to blow away the molten slag, forming a high-precision cut. Its key advantages are:

Oxygen Cutting: High speed, suitable for metals such as carbon steel, but a slight oxide layer will appear on the cut edge.

Nitrogen cutting: The cut surface is smooth and oxidation-free, allowing for direct welding. It is commonly used for high-requirement materials such as stainless steel, but the gas cost is high.

The choice between these two methods depends on the final workpiece's quality requirements and production cost control.

3.Revolutionary Advantages of Five-Axis Laser Cutting machine in Automotive Mold Manufacturing

One of the biggest challenges in traditional mold manufacturing is how to efficiently complete the trimming and precision punching of complex curved surfaces, especially in the production of large molds such as automotive body panels. Traditional methods often rely on repeated trial molding and welding corrections, which are not only time-consuming but also prone to material cracking leading to scrap.

By adopting five-axis laser cutting technology, companies can completely optimize their processes:

A:Directly replace trimming and punching dies with lasers, quickly cutting based on the formed sample from the drawing die, eliminating the intermediate punching and trimming processes.

B:Real-time adjustment of the cutting path, combined with digital inspection data for instant optimization, avoids multiple rework processes.

C:Reduced material waste, less reliance on highly skilled fitters, and avoidance of reduced mold life due to multiple welding repairs.

This transformation not only shortens mold development cycles by 30% to 50% but also significantly reduces manufacturing costs, making it highly favored by leading global automotive mold manufacturers.

4.Intelligent Programming and Process Optimization of the laser cutting machine : The Power of PEPS Software

In multi-axis laser cutting, precise fixture positioning and path planning are crucial. Camtek's PEPS software offers a highly efficient solution:

A.Intelligent Fixture Design: Automatically generates support structures to ensure stable workpiece fixation.

B.Adaptive Tool Axis Control: Dynamically adjusts the laser head angle to avoid energy buildup or cutting defects caused by changes in surface curvature.

C.Optimal Cutting Sequence: Follows the principle of "holes first, then edges; inside first, then outside," reducing the impact of stress deformation on accuracy.

Compared to traditional complex CAM systems, PEPS' intuitive operation and efficient simulation significantly lower the technical barrier, making five-axis programming more efficient and reliable.

5.Current Challenges and Future Prospects of the laser cutting machine

Despite the significant advantages of five-axis laser cutting technology, its high equipment investment and the difficulty of process optimization still somewhat limit its widespread adoption. In the future, with the improvement of laser source performance and the advancement of intelligent programming software, this technology is expected to be applied on a large scale in more industries, driving mold manufacturing towards intelligent production with higher precision and lower cost.

content is empty!

content is empty!