Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

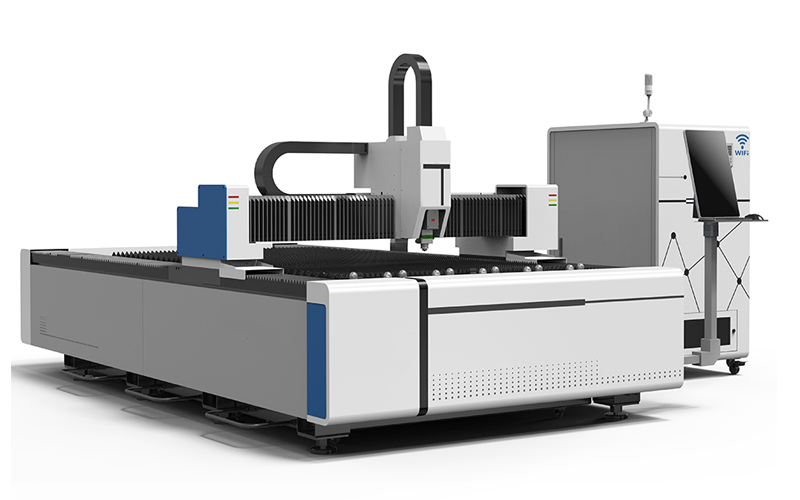

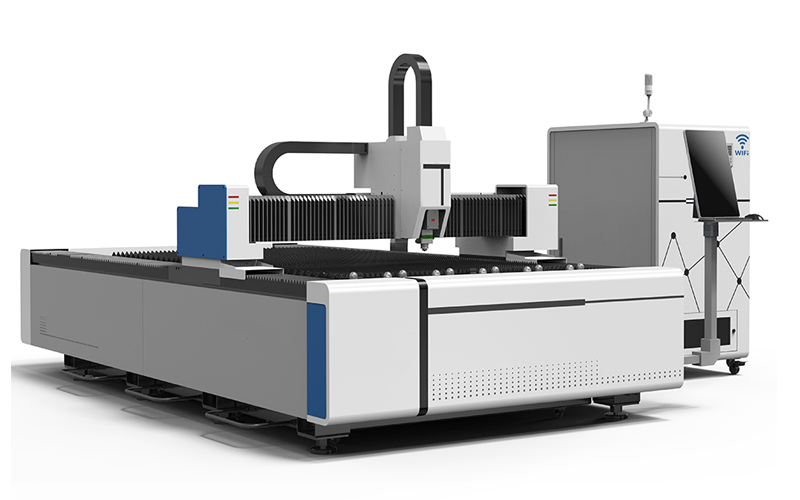

2KW Fiber Laser Cutting Machine – Precision, Speed & Efficiency for Metal Fabrication

Introduction of the fiber laser cutting machine:

In today’s competitive metal fabrication industry, precision and efficiency are key. Our 2KW fiber laser cutting machine is designed to deliver high-speed, high-quality cutting for a wide range of metals, making it ideal for workshops, factories, and manufacturing businesses.

Built with advanced fiber laser technology, this machine ensures smooth, burr-free cuts on stainless steel, carbon steel, aluminum, copper, and more—with minimal energy consumption. Whether you’re processing thin sheets or medium-thickness plates, our 2KW laser cutter maximizes productivity while reducing waste.

The Advantage of 2KW Fiber Laser Cutting Machine

1.Wide Industry Applications

1.Wide Industry Applications

Our 2KW laser cutter is widely used in:

✔ Metal fabrication (auto parts, machinery components)

✔ Kitchenware & appliances (sinks, panels)

✔ Advertising & decorations (metal letters, signage)

✔ Elevators & construction materials (steel frames, railings)

2.High-Speed & Precision Cutting of the fiber laser cutting machine

Cutting Thickness Range:

Carbon Steel: ≤13mm

Stainless Steel: ≤6mm

Aluminum: ≤4mm

Copper/Brass: ≤4mm

3. Low Operating Cost & High Stability of the laser machine

3. Low Operating Cost & High Stability of the laser machine

Electricity Consumption: It is far more efficient than plasma or CO₂ lasers.

Long Lifespan: 100,000+ hours of laser source lifespan with minimal maintenance.

High Stability: water-cooled ensure continuous operation without overheating.

4. The fiber laser machine is User-Friendly & Smart Features

Automatic Focus Adjustment for different material thicknesses

Industrial PC & Touchscreen Control with CAD/CAM compatibility

Automatic Nozzle & Capacitive Height Adjustment for consistent cutting quality

Automatic Lubrication System to extend machine lifespan

5.Technical Specifications of The fiber laser cutting machine

Model | Fiber laser cutting machine |

Working Area | 1500*3000mm |

Laser Power | 2kw |

Laser Generator | Max |

Laser Wave Length | 1064nm |

Working Table | Sawtooth-table |

Maximum Idle Running Speed | 140m/min |

Maximum acceleration | 1.5G |

Position Accuracy | ±0.02mm/m |

Repeat Positional Accuracy | ± 0.01mm |

Control System | PC control with CYPCUT |

Position Type | red dot |

Power Consumption | ≤8KW |

Working Voltage | 380V ±10 % 50/60Hz |

Auxiliary Gas | oxygen,nitrogen,air |

Working life of fiber module | More than 100000 hours |

Fiber laser cutting head | Raytools Auto focus BM110 laser cutting head |

Cooling System | Hanli industrial water chiller |

Work Environment | 0-45°C, Moisture 45-85% |

Delivery time | 25 working days |

6.The fiber laser cutting Machine Main Parts display

*We use Bochu controller FASCUT2000E:

*We use Bochu controller FASCUT2000E:

✅ Wide Format Support – Works with DXF, PLT, LXD & more

✅ Auto Layout & Editing – Save time with smart nesting & mode detection

✅ Precision Edge-Finding – Multiple methods for accurate positioning

✅ 1-Click Path Optimization – Faster setup, smoother cuts

*We use fiber laser generator Max:

✔ Zero Light Leakage – 100% sealed beam when off

✔ Compact & Powerful – Small footprint, massive output

✔ Ultra-Precise Pulses – High peak power with adjustable rates

✔ Built to Last – Military-grade reliability, extended lifespan

*We use Raytools auto focus laser cutting head BM110

✔ Modular Design – Easy maintenance, minimal downtime

✔ Triple-Lens Protection – Superior shielding for collimating & focusing

✔ Military-Grade Dustproof – IP65 sealed + patented lens cover (zero blind spots)

✔ Closed-Loop Auto Focus – Stepper motor precision, 0.01mm repeat accuracy

✔ Lightning Focus Speed – 100mm/s with industrial-grade stability

We use Delta servo motor and driver

Adopt Delta servo motor , and the closed-loop control method to ensure accurate positioning and dynamic response of the optimum acceleration, which makes the automatic positioning mechanism run smoothly and reliably, and is maintenance-free.

We use Hanli industrial water chiller

We use Hanli industrial water chiller

✔ Crystal-Clean Water – Ultra-pure cooling, ±0.1°C precision control

✔ Built for 24/7 Reliability – >99% uptime, 40% energy savings

✔ Military-Grade Tough – Self-protection systems, near-zero failures

We use France MOTOVARIO Reducer

Compared with other reducers, Motoly reducer has high rigidity, high precision, high transmission efficiency, low noise and long life

Modoli reducer is a special reducer for private servers, mainly used to reduce speed, increase torque, and match inertia

7.Advantages Over Competing Machines

* Higher cutting speed than 1.5KW models

*Lower operating cost vs. Plasma laser cutters

*Better edge quality than plasma cutters

*Versatile materials compatibility (including reflective metals like brass & copper)

8.The Cutting Samples of the fiber laser cutting machine

2KW Fiber Laser Cutting Machine – Precision, Speed & Efficiency for Metal Fabrication

Introduction of the fiber laser cutting machine:

In today’s competitive metal fabrication industry, precision and efficiency are key. Our 2KW fiber laser cutting machine is designed to deliver high-speed, high-quality cutting for a wide range of metals, making it ideal for workshops, factories, and manufacturing businesses.

Built with advanced fiber laser technology, this machine ensures smooth, burr-free cuts on stainless steel, carbon steel, aluminum, copper, and more—with minimal energy consumption. Whether you’re processing thin sheets or medium-thickness plates, our 2KW laser cutter maximizes productivity while reducing waste.

The Advantage of 2KW Fiber Laser Cutting Machine

1.Wide Industry Applications

1.Wide Industry Applications

Our 2KW laser cutter is widely used in:

✔ Metal fabrication (auto parts, machinery components)

✔ Kitchenware & appliances (sinks, panels)

✔ Advertising & decorations (metal letters, signage)

✔ Elevators & construction materials (steel frames, railings)

2.High-Speed & Precision Cutting of the fiber laser cutting machine

Cutting Thickness Range:

Carbon Steel: ≤13mm

Stainless Steel: ≤6mm

Aluminum: ≤4mm

Copper/Brass: ≤4mm

3. Low Operating Cost & High Stability of the laser machine

3. Low Operating Cost & High Stability of the laser machine

Electricity Consumption: It is far more efficient than plasma or CO₂ lasers.

Long Lifespan: 100,000+ hours of laser source lifespan with minimal maintenance.

High Stability: water-cooled ensure continuous operation without overheating.

4. The fiber laser machine is User-Friendly & Smart Features

Automatic Focus Adjustment for different material thicknesses

Industrial PC & Touchscreen Control with CAD/CAM compatibility

Automatic Nozzle & Capacitive Height Adjustment for consistent cutting quality

Automatic Lubrication System to extend machine lifespan

5.Technical Specifications of The fiber laser cutting machine

Model | Fiber laser cutting machine |

Working Area | 1500*3000mm |

Laser Power | 2kw |

Laser Generator | Max |

Laser Wave Length | 1064nm |

Working Table | Sawtooth-table |

Maximum Idle Running Speed | 140m/min |

Maximum acceleration | 1.5G |

Position Accuracy | ±0.02mm/m |

Repeat Positional Accuracy | ± 0.01mm |

Control System | PC control with CYPCUT |

Position Type | red dot |

Power Consumption | ≤8KW |

Working Voltage | 380V ±10 % 50/60Hz |

Auxiliary Gas | oxygen,nitrogen,air |

Working life of fiber module | More than 100000 hours |

Fiber laser cutting head | Raytools Auto focus BM110 laser cutting head |

Cooling System | Hanli industrial water chiller |

Work Environment | 0-45°C, Moisture 45-85% |

Delivery time | 25 working days |

6.The fiber laser cutting Machine Main Parts display

*We use Bochu controller FASCUT2000E:

*We use Bochu controller FASCUT2000E:

✅ Wide Format Support – Works with DXF, PLT, LXD & more

✅ Auto Layout & Editing – Save time with smart nesting & mode detection

✅ Precision Edge-Finding – Multiple methods for accurate positioning

✅ 1-Click Path Optimization – Faster setup, smoother cuts

*We use fiber laser generator Max:

✔ Zero Light Leakage – 100% sealed beam when off

✔ Compact & Powerful – Small footprint, massive output

✔ Ultra-Precise Pulses – High peak power with adjustable rates

✔ Built to Last – Military-grade reliability, extended lifespan

*We use Raytools auto focus laser cutting head BM110

✔ Modular Design – Easy maintenance, minimal downtime

✔ Triple-Lens Protection – Superior shielding for collimating & focusing

✔ Military-Grade Dustproof – IP65 sealed + patented lens cover (zero blind spots)

✔ Closed-Loop Auto Focus – Stepper motor precision, 0.01mm repeat accuracy

✔ Lightning Focus Speed – 100mm/s with industrial-grade stability

We use Delta servo motor and driver

Adopt Delta servo motor , and the closed-loop control method to ensure accurate positioning and dynamic response of the optimum acceleration, which makes the automatic positioning mechanism run smoothly and reliably, and is maintenance-free.

We use Hanli industrial water chiller

We use Hanli industrial water chiller

✔ Crystal-Clean Water – Ultra-pure cooling, ±0.1°C precision control

✔ Built for 24/7 Reliability – >99% uptime, 40% energy savings

✔ Military-Grade Tough – Self-protection systems, near-zero failures

We use France MOTOVARIO Reducer

Compared with other reducers, Motoly reducer has high rigidity, high precision, high transmission efficiency, low noise and long life

Modoli reducer is a special reducer for private servers, mainly used to reduce speed, increase torque, and match inertia

7.Advantages Over Competing Machines

* Higher cutting speed than 1.5KW models

*Lower operating cost vs. Plasma laser cutters

*Better edge quality than plasma cutters

*Versatile materials compatibility (including reflective metals like brass & copper)

8.The Cutting Samples of the fiber laser cutting machine

content is empty!