Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

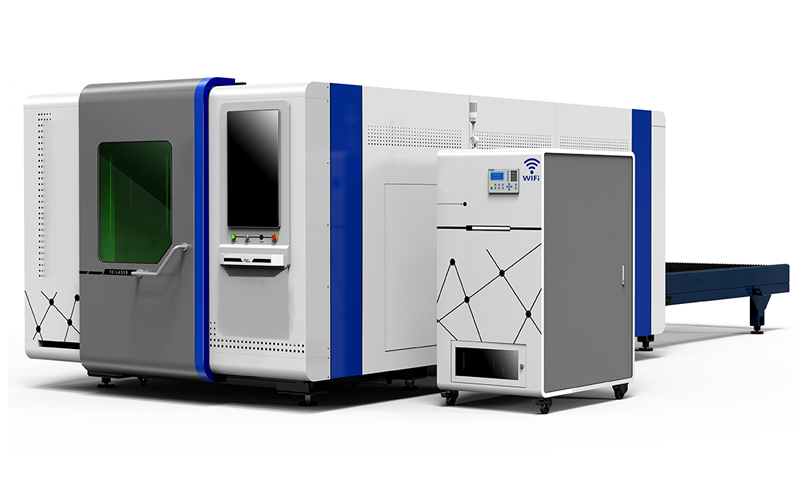

The 3015-3KW Fiber Laser Cutting Machine with Enclosed Exchange Table is a high-performance industrial laser cutter designed for precision, efficiency, and automation. Built for sheet metal fabrication, automotive parts, aerospace components, and machinery manufacturing, this machine delivers ultra-fast cutting, exceptional accuracy, and seamless batch processing.

Key Features & Advantages of the fiber laser cutting machine

1️⃣ High-Power 3KW Fiber Laser Source

Cutting Thickness: Up to 20mm (carbon steel), 12mm (stainless steel), 8mm (aluminum)**

Exceptional Beam Quality (≤0.08mm in diameter) ensures clear, burr-free edges.

Lower Power Consumption compared to CO₂ lasers, offering 30% higher energy efficiency.

2️⃣ Enclosed Exchange Worktable for Continuous Production

Dual-Pallets (A & B Tables) – Load/unload sheets while cutting, reducing downtime.

Heavy-Duty Structure – Supports up to 4000kg per table, handling large materials.

Automatic Switching – Seamless table exchange in seconds.

3️⃣ Advanced CNC & Motion Control

High-Speed Linear Guide Rails & Servo Motors – 120m/min rapid traverse, 4G acceleration.

0.01mm Repeat Positioning Accuracy for ultra-precise part consistency.

Latest DSP Control System with AI-based adaptive cutting parameters.

4️⃣ Intelligent Cutting & Safety Systems

Collision Avoidance System – Stops motion if material is misaligned.

Automatic Nozzle & Focus Adjustment – Reduces manual calibration time.

MAXor Raycus Fiber Laser (Optional) – World-class laser source reliability.

Fully Enclosed Body & Fume Extraction – Complies with CE & OSHA safety standards.

The Fiber Laser Cutting Machine Configuration

We use Bochu controller FASCUT2000E systerm

✅ File Compatibility – Supports DXF, PLT, LXD, and other standard formats.

✅ Smart Editing – Automatic internal/external contour recognition for faster setup.

✅ Auto Nesting – Optimizes material usage with intelligent layout.

✅ Precision Edge-Finding – Multiple methods for accurate positioning (±0.01mm).

✅ One-Click Path Optimization – Efficient cutting sequence for faster production.

We use 3000W Max Fiber Laser Generator

Fast: Cuts 20mm steel, 12mm stainless, 8mm aluminum quickly.

Efficient: Saves energy (30%+ conversion rate), long 100k-hour life.

Precise: Ultra-fine beam (≤0.01mm) for clean cuts.

Versatile: Works on steel, copper, brass, etc.

Smart: Auto-adjusts power/focus for different materials.

We use Raytools BM110 auto focus laser cutting head

Auto Focus: Instant adjustment for different material thicknesses.

High Precision: Sharp, stable beam for clean cuts.

Durability: Robust design for heavy-duty use.

We use Delta Servo motor and Driver

Precision Control: High accuracy for stable speed/torque.

High Performance: Rapid response, wide speed range

Energy Efficient: Regenerative braking reduces power consumption.

Compact & Robust: Durable design for industrial environments.

Easy Integration: Supports CANopen, Modbus, and EtherCAT.

The fiber laser cutting machine Technical Specifications (3015 Model)

The fiber laser cutting machine Technical Specifications (3015 Model)

Parameter | Specification |

Model | 3015-3KW (Enclosed Exchange Table) |

Laser Power | 3000W Fiber Laser (MAX/Raycus optional) |

Cutting Area | 3000mm x 1500mm (3m x 1.5m) |

Max Sheet Weight | 4000kg (per table) |

Positioning Accuracy | ±0.03mm |

Repeat Positioning | ±0.01mm |

Max Cutting Thickness | 20mm (Mild Steel), 12mm (Stainless), 8mm (Aluminum) |

Table Type | Dual automatic exchange pallets |

Control System | Fascut 2000E |

Gas Requirements | Oxygen / Nitrogen / Air |

Exhaust System | High-power extraction + Air Filter |

Machine Dimensions | ~5000mm x 3000mm x 2000mm (L x W x H) |

Weight | ~5000kg |

Why Choose This Fiber Laser Cutting Machine?

1. Fully Automated Production – No manual loading delays, maximizing uptime by 50%.

2.Laser Cutting for Industrial Needs – Ideal for metal workshops, automotive, HVAC, and shipbuilding.

3. Long-Term Cost Savings – Fiber laser cuts at lower operating costs than plasma or CO₂.

4.24/7 Durability – Built-in heat dissipation & anti-vibration structure for heavy-duty use.

5.Smart Cutting Technology – Nest multiple parts automatically to save material.

Applications of the fiber laser cutting machine

This high-efficiency 3KW fiber laser cutter is designed for continuous production in industries requiring fast, precision metal cutting:

1️⃣ Automotive & Machinery Manufacturing

Chassis, brackets, exhaust parts – High-speed cutting with ±0.01mm accuracy.

Batch processing – Uninterrupted production with dual-pallet exchange.

2️⃣ Sheet Metal Fabrication (HVAC, Electronics, Furniture)

Stainless steel/aluminum panels – Smooth, burr-free edges for enclosures, cabinets.

Nested cutting – Optimizes material usage for cost savings.

3️⃣ Aerospace & Defense

Thin-to-medium metal components – Up to 12mm stainless steel/aluminum with minimal heat distortion.

4️⃣ Industrial Part Production

Hydraulic fittings, gears, frames – 20mm carbon steel cutting capability.

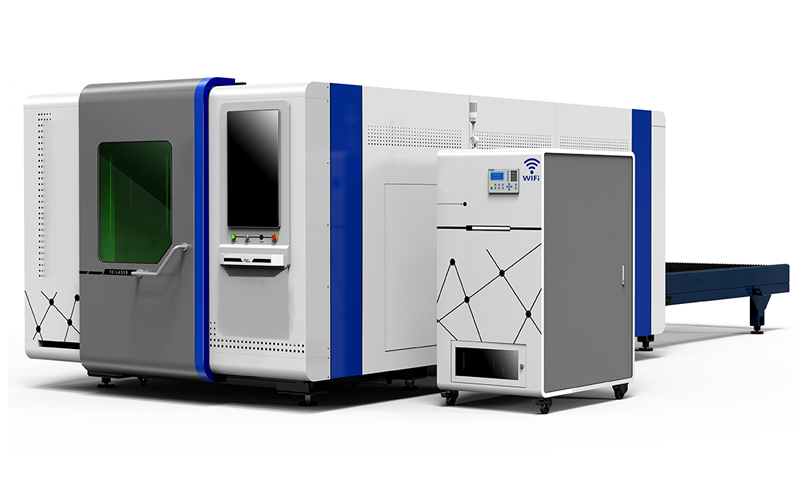

The 3015-3KW Fiber Laser Cutting Machine with Enclosed Exchange Table is a high-performance industrial laser cutter designed for precision, efficiency, and automation. Built for sheet metal fabrication, automotive parts, aerospace components, and machinery manufacturing, this machine delivers ultra-fast cutting, exceptional accuracy, and seamless batch processing.

Key Features & Advantages of the fiber laser cutting machine

1️⃣ High-Power 3KW Fiber Laser Source

Cutting Thickness: Up to 20mm (carbon steel), 12mm (stainless steel), 8mm (aluminum)**

Exceptional Beam Quality (≤0.08mm in diameter) ensures clear, burr-free edges.

Lower Power Consumption compared to CO₂ lasers, offering 30% higher energy efficiency.

2️⃣ Enclosed Exchange Worktable for Continuous Production

Dual-Pallets (A & B Tables) – Load/unload sheets while cutting, reducing downtime.

Heavy-Duty Structure – Supports up to 4000kg per table, handling large materials.

Automatic Switching – Seamless table exchange in seconds.

3️⃣ Advanced CNC & Motion Control

High-Speed Linear Guide Rails & Servo Motors – 120m/min rapid traverse, 4G acceleration.

0.01mm Repeat Positioning Accuracy for ultra-precise part consistency.

Latest DSP Control System with AI-based adaptive cutting parameters.

4️⃣ Intelligent Cutting & Safety Systems

Collision Avoidance System – Stops motion if material is misaligned.

Automatic Nozzle & Focus Adjustment – Reduces manual calibration time.

MAXor Raycus Fiber Laser (Optional) – World-class laser source reliability.

Fully Enclosed Body & Fume Extraction – Complies with CE & OSHA safety standards.

The Fiber Laser Cutting Machine Configuration

We use Bochu controller FASCUT2000E systerm

✅ File Compatibility – Supports DXF, PLT, LXD, and other standard formats.

✅ Smart Editing – Automatic internal/external contour recognition for faster setup.

✅ Auto Nesting – Optimizes material usage with intelligent layout.

✅ Precision Edge-Finding – Multiple methods for accurate positioning (±0.01mm).

✅ One-Click Path Optimization – Efficient cutting sequence for faster production.

We use 3000W Max Fiber Laser Generator

Fast: Cuts 20mm steel, 12mm stainless, 8mm aluminum quickly.

Efficient: Saves energy (30%+ conversion rate), long 100k-hour life.

Precise: Ultra-fine beam (≤0.01mm) for clean cuts.

Versatile: Works on steel, copper, brass, etc.

Smart: Auto-adjusts power/focus for different materials.

We use Raytools BM110 auto focus laser cutting head

Auto Focus: Instant adjustment for different material thicknesses.

High Precision: Sharp, stable beam for clean cuts.

Durability: Robust design for heavy-duty use.

We use Delta Servo motor and Driver

Precision Control: High accuracy for stable speed/torque.

High Performance: Rapid response, wide speed range

Energy Efficient: Regenerative braking reduces power consumption.

Compact & Robust: Durable design for industrial environments.

Easy Integration: Supports CANopen, Modbus, and EtherCAT.

The fiber laser cutting machine Technical Specifications (3015 Model)

The fiber laser cutting machine Technical Specifications (3015 Model)

Parameter | Specification |

Model | 3015-3KW (Enclosed Exchange Table) |

Laser Power | 3000W Fiber Laser (MAX/Raycus optional) |

Cutting Area | 3000mm x 1500mm (3m x 1.5m) |

Max Sheet Weight | 4000kg (per table) |

Positioning Accuracy | ±0.03mm |

Repeat Positioning | ±0.01mm |

Max Cutting Thickness | 20mm (Mild Steel), 12mm (Stainless), 8mm (Aluminum) |

Table Type | Dual automatic exchange pallets |

Control System | Fascut 2000E |

Gas Requirements | Oxygen / Nitrogen / Air |

Exhaust System | High-power extraction + Air Filter |

Machine Dimensions | ~5000mm x 3000mm x 2000mm (L x W x H) |

Weight | ~5000kg |

Why Choose This Fiber Laser Cutting Machine?

1. Fully Automated Production – No manual loading delays, maximizing uptime by 50%.

2.Laser Cutting for Industrial Needs – Ideal for metal workshops, automotive, HVAC, and shipbuilding.

3. Long-Term Cost Savings – Fiber laser cuts at lower operating costs than plasma or CO₂.

4.24/7 Durability – Built-in heat dissipation & anti-vibration structure for heavy-duty use.

5.Smart Cutting Technology – Nest multiple parts automatically to save material.

Applications of the fiber laser cutting machine

This high-efficiency 3KW fiber laser cutter is designed for continuous production in industries requiring fast, precision metal cutting:

1️⃣ Automotive & Machinery Manufacturing

Chassis, brackets, exhaust parts – High-speed cutting with ±0.01mm accuracy.

Batch processing – Uninterrupted production with dual-pallet exchange.

2️⃣ Sheet Metal Fabrication (HVAC, Electronics, Furniture)

Stainless steel/aluminum panels – Smooth, burr-free edges for enclosures, cabinets.

Nested cutting – Optimizes material usage for cost savings.

3️⃣ Aerospace & Defense

Thin-to-medium metal components – Up to 12mm stainless steel/aluminum with minimal heat distortion.

4️⃣ Industrial Part Production

Hydraulic fittings, gears, frames – 20mm carbon steel cutting capability.

content is empty!