Please Choose Your Language

| Availability: | |

|---|---|

| Quantity: | |

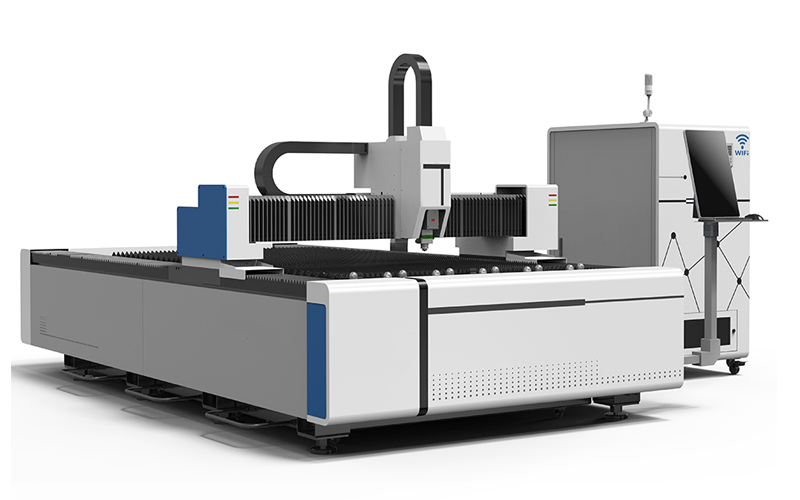

The Ultimate Guide To Professional Laser Cutting Machines – Precision, Speed & Versatility

Introduction of the fiber laser cutting machine:

Introduction of the fiber laser cutting machine:

In today's fast-evolving manufacturing and fabrication industries, precision and efficiency are crucial. Laser cutting machines have

revolutionized metalworking and other material processing applications by offering unmatched accuracy, speed, and versatility.

Whether you're in automotive, aerospace, electronics, or artistic fabrication, investing in a high-performance laser cutter ensures clean cuts, reduced waste, and increased productivity. In this article, we’ll explore how laser cutting works, its key advantages, applications, and why our machines stand out.

How Does The Laser Cutting Machine Work?

The Fiber Laser cutting Machine is a non-contact, thermal-based process where a high-powered laser beam melts, vaporizes, or burns through material to create precise cuts.

Here's how the fiber laser cutting machine works:

1.Laser Generation – A Fiber laser source emits a concentrated light beam.

2.Beam Focusing – Mirrors and lenses direct and sharpen the beam to a tiny focal point.

3.Material Cutting – The intense heat vaporizes or melts the material, while an assist gas (nitrogen, oxygen, or compressed air) blows away debris for a clean edge.

4.CNC Precision – A computer-controlled system (CNC) moves the laser head along programmed paths to achieve complex shapes.

Key Advantages of Our Professional Laser Cutting Machines

1. Unmatched Precision (±0.1mm Tolerance)

Ideal for intricate designs, micro-cuts, and high-tolerance industrial parts.

No mechanical blade wear ensures consistent accuracy over time.

2. Superior Speed & Efficiency ⚡

Cuts 5x faster than traditional methods (plasma, waterjet, or mechanical cutting).

Automated material handling reduces downtime.

3. Multi-Material Compatibility ️

Metals: Stainless steel, carbon steel, aluminum, brass, copper.

4. Smooth, Burr-Free Edges ✨

No secondary finishing required (unlike plasma or mechanical cutting).

Perfect for aerospace, medical devices, and automotive components.

5. Energy-Efficient & Cost-Effective

Fiber lasers consume 30% less power than CO₂ alternatives.

Reduced material waste = lower production costs.

6. Smart Automation & User-Friendly Software ️

Compatible with AutoCAD, CorelDRAW, SolidWorks, and more.

Auto-focus, nesting optimization, and IoT connectivity for Industry 4.0 integration.

7. Low Maintenance & Long Lifespan ⏳

Fiber lasers last 100,000+ hours (vs. CO₂ lasers at 20,000-30,000 hours).

Minimal consumables (no mirrors/laser tubes to replace frequently).

Core Configuration of the fiber laser cutting machine – Built for Maximum Productivity

1. Ultra-High Power Fiber Laser (6KW MAX)

*Thick metal mastery: Cuts 0.5–40mm carbon steel, 0.5–25mm stainless steel, and 0.5–20mm aluminum effortlessly.

*Up to 30% faster than 4KW lasers – reduces production time.

*Longer service life (100,000+ hours) with minimal energy consumption.

2. BOCHU4000E CNC System

*Ultra-stable motion control for high-speed precision (±0.03mm repeatability).

*Advanced AI anti-collision senses material variations for accident prevention.

3. Heavy-Duty Bed & Frame (20mm Steel, Reinforced Gantry)

*Vibration-resistant design – ensures stability even at 50m/min cutting speed.

*Dual-drive servos (Yaskawa /FUJI/ Delta) eliminate backlash for smoother motion.

4. We use BociBLT421 fiber laser cutting head,

*It can Automatic Nozzle & Capacitive Height Control (Auto Focus)

*Real-time Z-axis adjustment (±0.1mm accuracy) for irregular surfaces.

5.Hanli Industrial Chiller & Cooling System

*Precision temp control (±1°C) extends laser source lifespan.

*Dual-circuit cooling prevents overheating during operation.

6. Ready Smart Monitoring (4G/5G Connectivity)

*Remote diagnostics & preventive maintenance alerts.

*Production analytics tracks efficiency, uptime, and energy use.

Industries & Applications

✔ Metal Fabrication & Automotive

Exhaust pipes, chassis parts, gear components with precision-fit tolerances.

✔ Electronics & Medical Devices

Stents, micro-sensors, enclosures – Perfect for thin, delicate materials.

✔ Aerospace & Defense

Turbine blades, lightweight structural panels with complex geometries.

✔ Signage & Artistic Engraving

Custom logos, 3D reliefs, jewelry – Perfect for branding and artisans.

✔ Construction & HVAC

Ductwork, steel beams, ventilation panels – Faster than plasma cutting.

Why Choose Our Laser Cutting Machines?

1.Tailored Solutions – From 500W to 20KW power, accommodating small workshops to industrial plants.

2.Global Support – 24/7 technical assistance and on-site training.

3.CE, ISO, and FDA Certified – Ensures safety and compliance.

4.Competitive Warranty – Up to 3 years on laser sources & critical components.

The Ultimate Guide To Professional Laser Cutting Machines – Precision, Speed & Versatility

Introduction of the fiber laser cutting machine:

Introduction of the fiber laser cutting machine:

In today's fast-evolving manufacturing and fabrication industries, precision and efficiency are crucial. Laser cutting machines have

revolutionized metalworking and other material processing applications by offering unmatched accuracy, speed, and versatility.

Whether you're in automotive, aerospace, electronics, or artistic fabrication, investing in a high-performance laser cutter ensures clean cuts, reduced waste, and increased productivity. In this article, we’ll explore how laser cutting works, its key advantages, applications, and why our machines stand out.

How Does The Laser Cutting Machine Work?

The Fiber Laser cutting Machine is a non-contact, thermal-based process where a high-powered laser beam melts, vaporizes, or burns through material to create precise cuts.

Here's how the fiber laser cutting machine works:

1.Laser Generation – A Fiber laser source emits a concentrated light beam.

2.Beam Focusing – Mirrors and lenses direct and sharpen the beam to a tiny focal point.

3.Material Cutting – The intense heat vaporizes or melts the material, while an assist gas (nitrogen, oxygen, or compressed air) blows away debris for a clean edge.

4.CNC Precision – A computer-controlled system (CNC) moves the laser head along programmed paths to achieve complex shapes.

Key Advantages of Our Professional Laser Cutting Machines

1. Unmatched Precision (±0.1mm Tolerance)

Ideal for intricate designs, micro-cuts, and high-tolerance industrial parts.

No mechanical blade wear ensures consistent accuracy over time.

2. Superior Speed & Efficiency ⚡

Cuts 5x faster than traditional methods (plasma, waterjet, or mechanical cutting).

Automated material handling reduces downtime.

3. Multi-Material Compatibility ️

Metals: Stainless steel, carbon steel, aluminum, brass, copper.

4. Smooth, Burr-Free Edges ✨

No secondary finishing required (unlike plasma or mechanical cutting).

Perfect for aerospace, medical devices, and automotive components.

5. Energy-Efficient & Cost-Effective

Fiber lasers consume 30% less power than CO₂ alternatives.

Reduced material waste = lower production costs.

6. Smart Automation & User-Friendly Software ️

Compatible with AutoCAD, CorelDRAW, SolidWorks, and more.

Auto-focus, nesting optimization, and IoT connectivity for Industry 4.0 integration.

7. Low Maintenance & Long Lifespan ⏳

Fiber lasers last 100,000+ hours (vs. CO₂ lasers at 20,000-30,000 hours).

Minimal consumables (no mirrors/laser tubes to replace frequently).

Core Configuration of the fiber laser cutting machine – Built for Maximum Productivity

1. Ultra-High Power Fiber Laser (6KW MAX)

*Thick metal mastery: Cuts 0.5–40mm carbon steel, 0.5–25mm stainless steel, and 0.5–20mm aluminum effortlessly.

*Up to 30% faster than 4KW lasers – reduces production time.

*Longer service life (100,000+ hours) with minimal energy consumption.

2. BOCHU4000E CNC System

*Ultra-stable motion control for high-speed precision (±0.03mm repeatability).

*Advanced AI anti-collision senses material variations for accident prevention.

3. Heavy-Duty Bed & Frame (20mm Steel, Reinforced Gantry)

*Vibration-resistant design – ensures stability even at 50m/min cutting speed.

*Dual-drive servos (Yaskawa /FUJI/ Delta) eliminate backlash for smoother motion.

4. We use BociBLT421 fiber laser cutting head,

*It can Automatic Nozzle & Capacitive Height Control (Auto Focus)

*Real-time Z-axis adjustment (±0.1mm accuracy) for irregular surfaces.

5.Hanli Industrial Chiller & Cooling System

*Precision temp control (±1°C) extends laser source lifespan.

*Dual-circuit cooling prevents overheating during operation.

6. Ready Smart Monitoring (4G/5G Connectivity)

*Remote diagnostics & preventive maintenance alerts.

*Production analytics tracks efficiency, uptime, and energy use.

Industries & Applications

✔ Metal Fabrication & Automotive

Exhaust pipes, chassis parts, gear components with precision-fit tolerances.

✔ Electronics & Medical Devices

Stents, micro-sensors, enclosures – Perfect for thin, delicate materials.

✔ Aerospace & Defense

Turbine blades, lightweight structural panels with complex geometries.

✔ Signage & Artistic Engraving

Custom logos, 3D reliefs, jewelry – Perfect for branding and artisans.

✔ Construction & HVAC

Ductwork, steel beams, ventilation panels – Faster than plasma cutting.

Why Choose Our Laser Cutting Machines?

1.Tailored Solutions – From 500W to 20KW power, accommodating small workshops to industrial plants.

2.Global Support – 24/7 technical assistance and on-site training.

3.CE, ISO, and FDA Certified – Ensures safety and compliance.

4.Competitive Warranty – Up to 3 years on laser sources & critical components.

content is empty!