Please Choose Your Language

Laser cutting is becoming increasingly popular, especially in crafts. But can it work on leather?In this article, we'll explore whether laser cutting is suitable for leather. We'll discuss the benefits, including precision and intricate designs, and how to achieve successful results.

Laser cutting uses a high-powered laser to vaporize materials. The laser beam focuses intensely on the surface, causing it to melt, burn, or vaporize, leaving precise cuts. Laser cutters are highly effective for detailed designs and shapes, offering accuracy that traditional cutting methods can't match. Various materials, such as wood, acrylic, and leather, can be cut using lasers.

Natural leather comes from animal hides, mainly cowhide, goat, and sheep. It's a great material for laser cutting because of its ability to absorb the laser's heat, allowing for clean, sharp cuts. The finished edges are typically smooth, with minimal fraying, making it ideal for fashion and craft projects.

Synthetic or faux leather mimics natural leather but is made from a plastic base like PVC or PU. While it can be laser cut, caution is needed, especially with materials containing PVC. These may release harmful fumes during the process, which can damage both the machine and the person working with it.

Laser cutting uses a concentrated beam of light aimed directly at the leather. This focused energy rapidly heats the material, causing it to vaporize along the cutting line. The vaporization process allows the laser to cut through the leather with extreme precision. As the laser beam moves, it leaves behind clean, sharp edges that are much neater than traditional cutting methods.

Leather typically doesn't fray when laser cut. The laser's heat seals the edges, preventing threads from pulling apart. However, some slight charring can occur. For a polished look, you may want to use a burnisher or other finishing tools to smooth out the edges and remove any dark marks.

Different leather types, like vegetable-tanned or chrome-tanned leather, react differently to the laser. Thicker leather may require more power or multiple passes for a clean cut. Adjusting your laser cutter's settings is crucial to avoid damaging the material. The thicker the leather, the slower you may need to go.

Power settings depend on the leather's thickness and type. Higher power works better for thicker materials, while thinner leather needs less power and faster cuts. Test cuts are important, as they help determine the best settings for each project. Adjusting speed can also impact the cut quality and edge finish.

Laser cutting leather can release fumes and odors, especially when working with synthetic materials. Proper ventilation is key. Using an air assist system or ensuring good airflow in the workspace will help reduce the buildup of harmful gases and keep the cutting process clean.

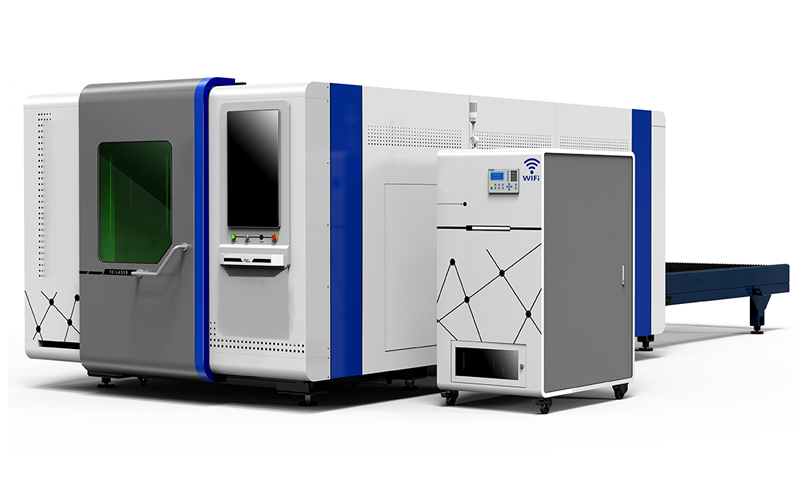

CO2 lasers are the top choice for cutting leather. Their wavelength of around 10.6 micrometers is absorbed well by organic materials like leather, making them ideal for precise cuts. CO2 lasers can cut through a wide range of leather types and thicknesses, producing clean, smooth edges without the need for post-cutting finishing.

Diode lasers are less powerful compared to CO2 lasers, but they still work well for cutting thinner leather. They're a more affordable option for hobbyists and DIY projects. While diode lasers can be effective, they may take longer to cut thicker materials and may not achieve the same precision as CO2 lasers.

The xTool P2 is a high-end CO2 laser cutter, ideal for small businesses or serious crafters. It offers excellent cutting speed and precision, with a larger working area. Its powerful 55W CO2 laser module can cut through thick leather quickly, making it perfect for both intricate designs and larger projects.

The xTool M1 is a versatile hybrid laser cutter and blade cutter, perfect for DIYers and hobbyists. It uses a 10W diode laser, which is great for cutting thinner leathers. It also has the added benefit of a blade cutting feature, making it a great all-in-one tool for crafting smaller leather goods and projects.

When choosing leather for laser cutting, make sure it's compatible with the laser cutter. Look for leather that is not too thick or treated with chemicals that could release harmful fumes. Natural leather, like cowhide or goat, is ideal because it reacts well to laser cutting. Check if the leather is pre-treated for laser use by contacting the supplier or doing a test cut.

Before cutting, ensure the leather is smooth and free of wrinkles. Use a flat surface and check for any imperfections that might interfere with the laser. Applying masking tape over the leather's surface can help prevent smoke marks from the laser. This also helps keep the edges clean and crisp.

Always do test cuts on scrap pieces of leather first. This allows you to adjust the laser settings, such as power and speed, to ensure the best results. Testing helps you avoid wasting leather and ensures your final cut is precise.

Laser cutting can bring your jewelry designs to life! Consider cutting unique earrings, necklaces, or bracelets. Intricate patterns or custom shapes are easy to achieve. Engraving your designs adds a personal touch, making each piece truly one-of-a-kind. You can engrave initials, logos, or meaningful symbols to personalize your creations.

Creating custom keychains is another great laser cutting project. You can cut out shapes like hearts, animals, or even logos. Engraving names or messages turns simple keychains into thoughtful gifts or marketing items. Adding hardware like key rings or clasps can elevate their functionality and style.

Laser cutting is perfect for designing wallets, bags, and other accessories. The precision of the laser allows for sleek, sharp cuts that simplify the process of assembling these products. You can also combine cutting with stitching for added durability. This technique is great for personalizing your designs, from adding monograms to creating intricate patterns.

Laser cutting can be used to design stunning purses and clutches. You can create detailed patterns that would be hard to achieve by hand. Whether you want a sleek, modern look or something more intricate, the laser cutter ensures precision. Patterns cut with a laser provide high-quality, professional finishes that make these accessories stand out.

To avoid burn marks, adjust the power and speed of the laser cutter based on the leather's thickness. Thicker leather needs more power and slower speeds. Also, the right laser focal length is crucial. Too long a focal length can result in a less clean cut, while too short may burn the leather.

Air assist nozzles blow a stream of air over the leather during cutting. This helps keep the leather cool and reduces the chance of burns. It also prevents the buildup of smoke and debris, keeping your cuts clean and precise.

Always wear proper safety equipment, such as goggles and gloves, when laser cutting leather. Ensure the workspace is well-ventilated to avoid inhaling fumes. It's also important to keep the area clean and free of dust, as this reduces the risk of fire and ensures smoother cutting.

After cutting, you may need to clean any charred edges. Use a soft cloth or fine sandpaper to gently buff away any burn marks. For a cleaner finish, you can use a burnishing tool to smooth the edges and ensure your final product looks polished.

If leather catches fire, it usually means the power is too high or the speed is too slow. To fix this, reduce the laser power and increase the speed. You can also use air assist to cool the leather during cutting, which helps prevent flames. Keep a close eye on the leather while cutting to quickly stop the machine if needed.

Uneven or poor cuts can happen if the laser settings aren't right for the leather. If this occurs, check the power and speed settings. Thicker leather needs slower cuts, while thinner leather requires faster, lower-power settings. Another issue could be the focal length of the laser—adjust it to ensure a consistent, clean cut.

Leather can be successfully laser cut with the right machine and settings. The process offers precision, speed, and intricate designs. To ensure success, follow best practices for adjusting settings and safety measures. If you're new to laser cutting, start small and experiment to achieve the best results.

A: The minimum laser power depends on the leather's thickness and type. For thinner leather, a 30W CO2 laser may be sufficient, but thicker leather requires more power, typically around 50W or higher.

A: To remove burn marks, gently sand the edges with fine-grit sandpaper or use a burnishing tool to smooth them out.

A: Yes, blade cutters can be used for leather, but laser cutters provide more precise and intricate cuts, especially for detailed designs.

A: Ensure proper ventilation in the workspace to dissipate the fumes. Using an air assist system can also help reduce odors during cutting.