Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-08-14 Origin: Site

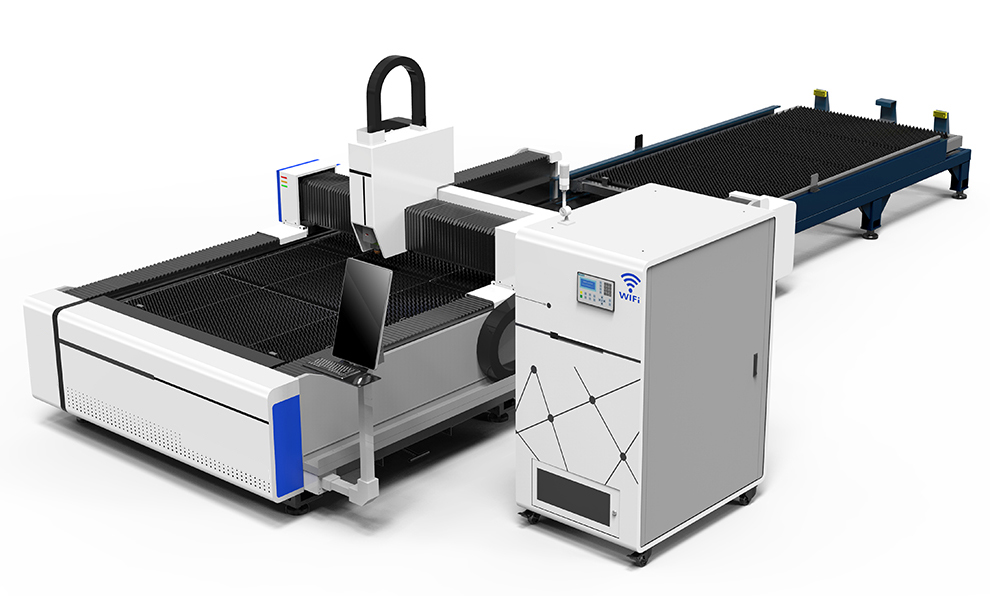

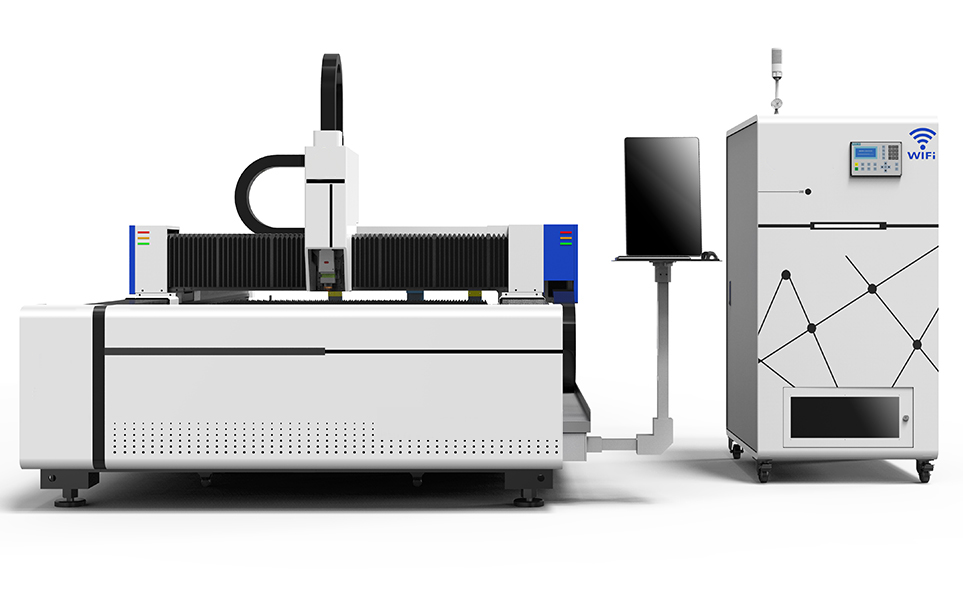

Ever wondered how laser cutting achieves such precise results? With tolerances as fine as 0.1 mm, it's a game-changer for industries requiring perfection.In this post, we'll explore what makes laser cutting so accurate and why it's essential for many applications.You’ll learn about its precision, the factors that affect it, and why it's the go-to method for industries like aerospace and medical manufacturing.

Laser cutting is incredibly precise due to its unique process and technology. Let’s break it down.

Lasers cut through materials by focusing intense light beams on the surface. The heat generated melts, burns, or vaporizes the material, leaving a clean, smooth edge. This allows for incredibly precise cuts, even on intricate designs.

Lasers can focus down to a small diameter, sometimes as tiny as 0.1 mm. The high-powered beam cuts through metals, plastics, and other materials with unmatched accuracy.

Laser cutters use powerful beams to maintain high heat, which enables fast, precise cutting. This consistent energy helps achieve tight tolerances, even on tough materials.

Laser cutting machines are controlled by Computer Numerical Control (CNC), ensuring that the laser follows exact paths. CNC allows for flawless replication of complex designs without human error.

Modern lasers use fiber optics to guide the laser beam. These optical fibers ensure that the beam stays focused, enhancing the precision of each cut. The technology minimizes the risk of deviation during the cutting process.

The combination of high-powered lasers, CNC control, and fiber optics ensures that laser cutting maintains consistent precision. The laser remains focused throughout the process, delivering exact results on every cut, even in long production runs.

Laser cutting is known for its impressive precision. Let’s dive into the key metrics that define how accurate laser cutting can be.

Laser cutting typically achieves an accuracy of ±0.1 mm. This means the cuts are accurate to about the thickness of a human hair.

What Does This Accuracy Mean for Industrial Applications?For many industries, such as automotive and aerospace, this level of precision ensures parts fit together perfectly, reducing the need for post-processing or adjustments.

Can Laser Cutting Reach Tighter Tolerances?Yes, with advancements in technology, laser cutting can achieve even tighter tolerances. In fact, some high-end machines can reach tolerances of ±0.05 mm or even better, allowing for highly detailed work.

Advanced laser cutting machines are designed to cut with extreme precision, reaching tolerances as tight as ±0.05 mm.

What Factors Influence the Ability to Achieve Such Tight Tolerances?Factors like laser beam size, material type, and machine quality all play a role. Smaller beam diameters and high-quality optics allow for finer, more accurate cuts.

Example Industries Using Ultra-Precise Laser Cutting

Aerospace: Parts with extremely tight tolerances are essential in this industry, where precision is critical for safety.

Medical Device Manufacturing: Laser cutting is used to produce surgical instruments with sharp, exact edges.

Electronics: Tiny components, such as connectors and enclosures, benefit from the high precision of laser cutting.

With its ability to reach such high levels of precision, laser cutting is becoming the go-to method for industries demanding tight tolerances.

Laser cutting precision can be influenced by several factors. Let's look at the key elements that impact the accuracy of the cuts.

How the Type of Material Affects Precision

Different materials respond to lasers differently. Metals, plastics, and glass all require specific settings. For example, metal absorbs laser energy differently than plastic, affecting the cut’s sharpness.

The Impact of Material Thickness on Laser Cutting Accuracy

Thicker materials tend to be harder to cut precisely. As the material thickness increases, the laser needs more power, which can cause heat distortion and reduce accuracy.

Differences Between Cutting Thin vs. Thick Materials

Thin materials are easier to cut accurately since they don’t require as much power. However, thicker materials require more time and precision to maintain consistent results.

How Beam Size Influences Cutting Precision

The size of the laser beam spot directly affects how fine the cuts are. A smaller spot size allows the laser to focus on narrower areas, increasing precision.

Why Smaller Spot Sizes Result in Finer Cuts

Smaller spots reduce the width of the kerf (the material removed during cutting). This results in finer, more detailed cuts, ideal for intricate designs and small components.

Relationship Between Laser Power and Cutting Speed

Laser power and cutting speed are closely linked. High power allows for faster cuts, while slower speeds give the laser more time to focus on the material for finer cuts.

How Optimizing Power and Speed Settings Can Improve Accuracy

By fine-tuning the power and speed, you can optimize the cut for different materials, reducing distortion and ensuring clean edges.

Adjusting Power Levels for Different Materials

Different materials require different power levels. For example, softer materials like wood need lower power than metals like steel, which require higher power settings.

Importance of Proper Workpiece Alignment

If the workpiece isn’t aligned properly, the laser may cut unevenly, reducing precision. Accurate positioning is key for consistent results.

How Vibrations and Instability Can Reduce Cutting Accuracy

Any movement or vibration during cutting can throw off the laser's path, resulting in less precise cuts. Stability is crucial.

Tips for Stabilizing Workpieces to Achieve Precise Cuts

Use clamps or a sturdy surface to prevent the workpiece from shifting. This helps maintain the laser’s focus and ensures clean, accurate cuts.

Laser cutting is a highly precise method, but how does it stack up against other cutting techniques? Let’s compare it to two popular methods: waterjet cutting and plasma cutting.

Key Differences in Accuracy Between Laser and Waterjet Cutting

Laser cutting offers much higher precision compared to waterjet cutting. While laser cutting can achieve tolerances of ±0.1 mm or better, waterjet cutting usually has tolerances of ±0.2 mm to ±0.5 mm. This makes laser cutting the preferred choice for detailed, intricate designs.

When to Choose Laser Cutting Over Waterjet Cutting

Choose laser cutting when you need clean, sharp cuts with tight tolerances. It’s ideal for thinner materials and applications requiring fine details. Waterjet cutting is better for thicker materials or when heat-affected zones (HAZ) need to be avoided.

Accuracy Comparison Between Laser Cutting and Plasma Cutting

Plasma cutting, though effective for thicker materials, is less accurate than laser cutting. Plasma cutting tends to leave a wider kerf and is more prone to heat distortion, reducing the precision of the cut. Laser cutting maintains a narrow kerf and delivers more consistent results.

When to Use Laser Cutting for More Precise Applications

Use laser cutting when high precision is crucial, such as in the aerospace, automotive, or medical device industries. Plasma cutting is better for thicker metals or when speed is more important than precision.

Laser cutting offers several benefits, especially when it comes to precision and efficiency. Here are the key advantages of its accuracy.

The Ability of Laser Cutters to Achieve Complex and Detailed Designs

Laser cutting can handle intricate shapes and detailed designs, thanks to its ability to focus on narrow areas. This precision makes it ideal for complex cuts and fine details, even on small parts.

Industries That Benefit from Intricate Cuts

Industries like aerospace, medical devices, and jewelry rely heavily on the accuracy of laser cutting. For example, in aerospace, it’s used to cut parts that require tight tolerances, while in jewelry, it enables the creation of fine, delicate pieces.

How Laser Cutting Ensures Identical Cuts Across Batches

Laser cutters are guided by CNC technology, ensuring identical cuts every time. Whether you're cutting one piece or thousands, the consistency remains the same, reducing human error.

The Importance of Consistency in Mass Production

Laser cutting is highly beneficial for mass production. Consistent accuracy across multiple parts helps reduce the need for rework, ensuring products meet the exact specifications.

How Laser Cutting Minimizes Kerf Width

The kerf width in laser cutting is extremely narrow, meaning less material is removed during the cutting process. This precise cutting helps minimize material waste, which is both cost-effective and environmentally friendly.

Benefits of Reduced Material Waste in Industrial and Environmental Terms

Reducing material waste lowers production costs and has a positive environmental impact. By using fewer raw materials, industries can decrease their environmental footprint while still producing high-quality products.

Laser cutting’s unmatched accuracy makes it a go-to technology for a variety of industries. Let’s explore some of the key sectors where laser cutting precision plays a vital role.

How Precision Laser Cutting Is Used in Aerospace Manufacturing

In aerospace, precision is critical for safety and performance. Laser cutting is used to manufacture complex, lightweight parts with tight tolerances, ensuring they fit perfectly into larger assemblies.

Examples of Parts Made with Laser Cutting Accuracy

Laser cutting is used for cutting turbine blades, structural components, and even lightweight panels. These parts require the kind of precision laser cutting delivers to meet strict aerospace standards.

The Role of Laser Cutting in Producing Medical Components

Laser cutting is ideal for producing medical components that demand high precision. It’s used to create parts like implants, surgical tools, and stents that must adhere to strict size and shape requirements.

Accuracy Required for Surgical Instruments and Medical Device Housings

Surgical instruments need to be precise, as even minor errors could lead to complications. Laser cutting allows for the creation of sharp, exact edges, critical for cutting-edge medical devices.

The Use of Laser Cutting for Detailed Jewelry Designs

Laser cutting is perfect for crafting intricate jewelry pieces. Whether it’s cutting fine rings, engraving patterns, or shaping delicate chains, laser cutters achieve the high level of detail needed in these small, intricate designs.

Why Laser Cutting Is Ideal for Producing Small, Intricate Pieces

Laser cutters can focus on areas as small as 0.1 mm, making them the best option for producing complex jewelry designs with sharp, clear edges without compromising on quality.

Laser Cutting’s Role in Producing High-Precision Automotive Parts

In the automotive industry, laser cutting is used to produce everything from body panels to engine components. These parts require exact measurements to ensure proper fit and functionality in complex systems.

How Laser Cutting Improves Safety and Performance in Automotive Components

Precision laser cutting ensures automotive parts are manufactured to exact specifications. This reduces the risk of failure and enhances safety, while also improving the overall performance of the vehicle.

To get the most out of your laser cutting system, you need to optimize settings, maintain your equipment, and choose the right cutter for the job. Here’s how you can improve laser cutting accuracy.

How to Adjust Settings for Different Materials and Thicknesses

Different materials require different laser settings. For example, thicker materials need more power, while thinner materials may require faster cutting speeds. Adjust the power, speed, and frequency based on the material and its thickness for optimal results.

The Role of Testing on Scrap Materials to Find the Right Parameters

Before cutting important materials, test your settings on scrap pieces. This helps you fine-tune the laser parameters, ensuring that you achieve the best cutting quality and minimize errors on your final product.

Importance of Machine Calibration for Maintaining Accuracy

Regular calibration of your laser machine is essential for maintaining accuracy. Over time, parts may wear out or shift, affecting the laser’s focus and alignment. Calibration ensures that the laser stays sharp and precise.

How Regular Maintenance Helps Sustain Precision in Laser Cutting

Routine maintenance, such as cleaning lenses and checking alignment, keeps the system working efficiently. Regular upkeep reduces the risk of misalignment, ensuring that every cut is as accurate as the last.

How to Select a Laser Cutter Based on Your Accuracy Needs

Not all laser cutters are the same. Choose a machine with the right precision for your specific needs. For intricate designs, select a high-precision laser cutter that can handle fine details and tight tolerances.

Differences Between Fiber Lasers, CO2 Lasers, and Crystal Lasers in Terms of Precision

Fiber lasers are known for their high precision and ability to cut metals. CO2 lasers are ideal for cutting non-metals and are less accurate on metals. Crystal lasers, on the other hand, offer versatility but may have slightly lower precision than fiber lasers for certain applications.

Laser cutting technology continues to evolve, with exciting developments that promise even greater precision in the future. Let’s take a look at where it's headed.

Emerging Trends in Laser Cutting Technology

New advancements are constantly improving laser cutting. For instance, laser cutters are becoming faster and more energy-efficient, allowing industries to reduce costs while maintaining accuracy. Additionally, laser cutting machines are becoming more user-friendly, integrating smarter software for easier operation.

How Artificial Intelligence and Machine Learning May Enhance Laser Cutting Precision

Artificial intelligence (AI) and machine learning (ML) are being integrated into laser cutting systems. These technologies can predict and adjust laser parameters in real-time, ensuring optimal cuts. AI can also help detect irregularities during the cutting process, preventing errors and improving overall precision.

Future Developments in Laser Cutting Equipment That Promise Even Tighter Tolerances

As laser technology advances, future machines may achieve even tighter tolerances, potentially reaching sub-micron levels. New innovations, such as advanced optical systems and adaptive focus technology, will help laser cutters make more precise adjustments, ensuring that every cut is as accurate as possible.

Laser cutting is known for its incredible accuracy, making it one of the most precise fabrication methods.

Its precision benefits industries like aerospace, medical devices, and jewelry, where accuracy is critical.

For businesses and manufacturers, laser cutting offers consistent, high-quality results, reducing waste and improving efficiency.

A: Laser cutting can achieve precision as fine as ±0.1 mm, with high-end machines reaching ±0.05 mm or better.

A: Laser cutting can handle metals, plastics, glass, and more, achieving high precision on both thin and thick materials.

A: Yes, laser cutting maintains consistent accuracy across both small and large production runs, ensuring identical cuts.

A: Laser cutting accuracy can be affected by material thickness, heat distortion, and machine calibration, especially with thicker materials.