Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

CNC laser cutting is revolutionizing manufacturing with its precision and speed. It's used across industries, from aerospace to jewelry. In this article, we'll explore how CNC laser cutting works, its advantages, and the types of machines involved. You'll also learn about the diverse applications and future trends in this technology.

CNC stands for Computer Numerical Control. It refers to the use of computer software to control machine tools and automate their movements. In the context of laser cutting, CNC allows the machine to precisely follow the design instructions and make accurate cuts. This technology eliminates manual errors and increases efficiency in the cutting process.

CNC laser cutting involves several key steps:

CAD Design Creation

First, a design is created using Computer-Aided Design (CAD) software. This digital design serves as the blueprint for the machine.

G-code Conversion for CNC Machines

The CAD file is then converted into G-code, which is a language that CNC machines understand. This code contains instructions for the machine's movements.

Material Placement and Machine Setup

The material to be cut, like metal, wood, or plastic, is placed on the machine's work surface. The machine is set up based on the material type and thickness.

Laser Cutting Process and Material Removal

Once everything is set up, the machine guides the laser beam along the programmed path. The laser melts, burns, or vaporizes the material, leaving a precise cut. A gas assist, like oxygen or nitrogen, helps remove the molten material and keeps the cut clean.

The laser's power affects both the cutting speed and the material thickness. Higher power is needed for thicker materials, but too much power can lead to heat distortion. Fine-tuning power and speed ensures optimal results with minimal waste and clean cuts.

CO2 Laser Cutters

CO2 lasers are one of the most common types of CNC lasers. They use carbon dioxide gas to generate a powerful laser beam. CO2 lasers work well with non-metal materials like wood, acrylic, and plastics. They also cut thinner metals efficiently, making them ideal for general-purpose use in industries like signage, furniture, and packaging.

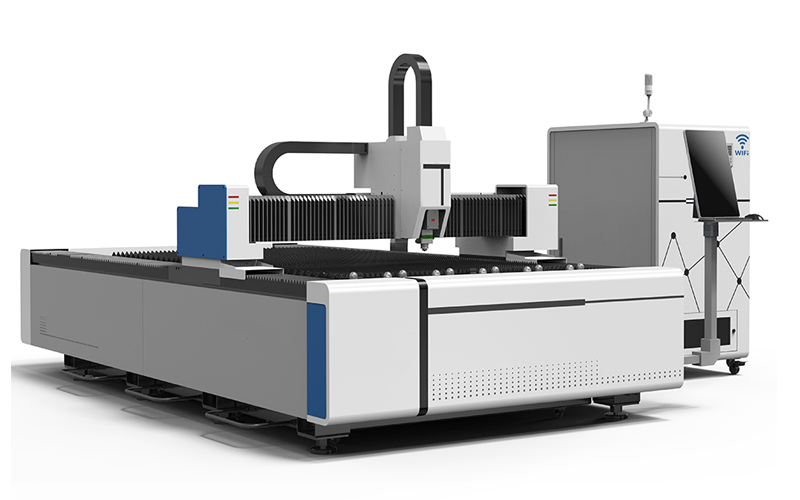

Fiber Laser Cutters

Fiber lasers use fiber optics to generate the laser beam. They offer high efficiency and precision, making them ideal for cutting metals, including aluminum, stainless steel, and brass. Fiber lasers excel in high-speed cutting and produce less heat than CO2 lasers. This makes them great for applications requiring intricate cuts, like electronics and automotive parts.

Crystal Laser Cutters (Nd:YAG)

Crystal lasers, like Nd:YAG, use a crystal medium to generate the laser. They are powerful and well-suited for cutting thicker metals. These lasers can work with various materials, including metals, ceramics, and glass. Nd:YAG lasers are commonly used in industries requiring high-intensity cutting, such as aerospace and heavy manufacturing.

Performance Comparison

CO2 lasers are generally less efficient than fiber lasers. Fiber lasers have higher power output and can cut faster, especially with metals. They are also more energy-efficient, reducing operating costs.

Material Compatibility

CO2 lasers handle non-metals better, like wood, plastic, and acrylic. Fiber lasers are more suited for cutting metals, especially thinner ones, with high precision.

Applications for Each Type

CO2 lasers are often used in industries like signage, furniture, and decorative products.

Fiber lasers shine in industries needing high-speed cutting, such as electronics, automotive, and metal fabrication.

CNC Controller

The CNC controller is the brain of the machine. It interprets the design file (usually in CAD format) and converts it into instructions for the laser cutter. These instructions guide the machine's movements, ensuring precise cutting.

Laser Source

The laser source generates the laser beam. Common types include CO2, fiber, and crystal (Nd:YAG) lasers. Each type has its strengths. CO2 lasers are great for non-metals, while fiber lasers excel in cutting metals.

Beam Delivery System

This system consists of mirrors and lenses, which direct and focus the laser beam onto the material. The mirrors guide the beam along the path, while lenses ensure that the laser is focused at the right spot.

Cutting Head

The cutting head focuses the laser beam onto the material and helps remove the melted or vaporized material. It also usually has a nozzle that directs assist gases (like oxygen or nitrogen) to improve the cut quality and remove debris.

Motion System

The motion system moves the cutting head along the X, Y, and sometimes Z axes. This movement allows the laser to trace the exact path defined by the design, cutting the material with high precision.

Design and CAD Programming

The process starts with creating a design using Computer-Aided Design (CAD) software. This design is then converted into G-code, a language that the CNC machine understands.

Material Preparation and Setup

The material to be cut is placed on the machine's work surface. The machine is configured based on the type and thickness of the material, ensuring the correct settings are in place for cutting.

Laser Cutting Operation

The CNC controller guides the laser head along the programmed path. The focused laser beam melts, vaporizes, or burns through the material, leaving a precise cut. Assist gases like oxygen or nitrogen help clear away the vaporized material, ensuring a clean cut.

Post-Processing

After cutting, the material may need further steps like deburring (removing sharp edges) and finishing (polishing the surface) to achieve the desired look and functionality.

Comparison with Traditional CNC Machining

Unlike traditional methods like milling or routing, CNC laser cutting is non-contact. There is no physical tool touching the material, reducing wear and tear and improving precision. Laser cutting also doesn't generate as much heat distortion.

Advantages of Laser Cutting

Laser cutting offers several advantages over traditional machining:

Precision: Achieves very fine cuts with high accuracy.

Speed: Faster cutting, especially for intricate designs.

Non-contact: Eliminates the risk of tool wear and material deformation.

High Precision and Tight Tolerances

CNC laser cutting delivers incredible precision, often with tolerances as tight as ±0.1mm. This makes it ideal for cutting intricate designs and detailed shapes.

Clean Cuts with Minimal Burrs

The non-contact nature of the laser cutting process results in clean cuts with minimal burrs or rough edges. This reduces the need for additional finishing work, saving time and labor costs.

Speed and Efficiency in Production

Laser cutting is faster compared to traditional methods, especially for intricate and detailed designs. It also automates much of the process, improving overall production efficiency.

Minimal Material Waste

Laser cutting is known for its precise cuts and narrow kerf width, ensuring minimal material waste. This allows manufacturers to maximize their material usage, saving money and reducing waste.

Reduced Energy Consumption

CNC laser cutters are energy-efficient machines. They consume less power than traditional machines, especially when cutting thinner materials, leading to lower operational costs and environmental impact.

Lower Material Waste and Recyclability of Metals

Laser cutting's precision reduces scrap material, and the materials used, such as metals, are often fully recyclable. This contributes to a more sustainable production process.

Less Heat Distortion and Material Damage

Since the laser beam heats a very small area, there's minimal heat distortion compared to other cutting methods. This reduces the chance of material damage and ensures a high-quality cut.

Metals

CNC laser cutting is perfect for a variety of metals like steel, aluminum, and brass. It works well with both thin and thick metal sheets, making it a popular choice for industries like automotive and aerospace.

Non-Metals

Laser cutting is also effective for non-metal materials such as wood, acrylic, plastic, rubber, and textiles. These materials are often used in industries like signage, interior design, and packaging.

Specialty Materials

CNC laser cutters can handle specialty materials, including glass, ceramics, and composites. However, extra care is required for cutting glass and ceramics to prevent damage.

Difficulty Cutting Reflective Materials

Reflective metals, like copper and brass, can be challenging for CNC lasers. The laser beam can reflect off these materials, which may cause the machine to malfunction or reduce cutting efficiency.

Challenges with Thick Materials and High-Powered Lasers

Cutting thick materials requires higher laser power, which can be a limitation in some cases. It may lead to slower cutting speeds, heat distortion, and other issues, especially when working with very thick metals.

Aerospace

CNC laser cutting is crucial for the aerospace industry, where narrow tolerances are necessary. It's used to cut parts for aircraft, ensuring they meet precise specifications.

Automotive

In the automotive industry, CNC laser cutting provides precision parts for car bodies and components. It's especially effective for creating detailed cuts in sheet metal.

Electronics

CNC laser cutters are widely used in electronics for cutting circuit boards and components. They offer precision and speed for intricate designs in small parts.

Medical

CNC laser cutting is used to make surgical instruments and implants, where high precision and sterile, clean cuts are essential.

Jewelry

In the jewelry industry, CNC lasers create intricate designs and engrave fine details in metals like gold and silver. It allows for high-quality, detailed craftsmanship.

Intricate Lettering and Logo Designs

Laser cutting allows for precise cuts of intricate lettering and logo designs in various materials. It's perfect for creating customized signage with clean, sharp edges.

Precision Cuts in Various Materials

CNC laser cutting works with materials like metal and acrylic, making it ideal for detailed and intricate signage that needs to withstand outdoor conditions.

Burn Marks

Burn marks occur when the laser generates too much heat on the material's surface. These marks can be avoided by adjusting the laser power and cutting speed. Using the right assist gas can also help prevent excessive heat buildup.

Dross

Dross is the molten material that solidifies at the bottom of the cut, creating unwanted residue. It happens when the cutting speed is too slow or the laser power is too high. To minimize dross, adjust the cutting speed, use the correct assist gas, and ensure proper focus.

Warping and Incomplete Cuts

Warping occurs when excessive heat causes the material to bend or distort. Incomplete cuts happen if the laser doesn't fully penetrate the material. These issues can be prevented by adjusting the laser power, speed settings, and focus. Using the right assist gas also plays a key role.

Laser Power and Speed Settings

The laser power determines how deep the cut will be, while the cutting speed affects the quality of the cut. Too much power can cause excessive heat, leading to burn marks or dross. Too little power may result in incomplete cuts. Adjusting both power and speed based on material type and thickness is key.

Material Thickness and Type

Thicker materials require more laser power, and different materials absorb the laser beam in different ways. For example, metals need higher power compared to wood or acrylic. Understanding the material's properties ensures optimal settings for a clean cut.

Gas Assist: Choosing the Right Gas for Cutting Efficiency

Using the right assist gas helps clear away molten material and supports the cutting process. Oxygen, nitrogen, and air are common choices. Oxygen is ideal for cutting metals, while nitrogen produces cleaner cuts without oxidation.

How to Prepare CAD Designs for Laser Cutting

Ensure your CAD designs are clean and clear. Use the correct file format (e.g., DXF, DWG) for CNC machines. Design with simple, precise lines and avoid overly complex shapes, which can lead to cutting errors.

Importance of Proper Kerf Width and Fit Tolerances

The kerf width is the width of the cut made by the laser. Make sure to account for this when designing parts that need to fit together. Adjusting for kerf width ensures better assembly and minimizes material waste.

Avoiding Complex Features That May Be Hard to Cut

Some features, like very small holes or tight corners, may be difficult for the laser to cut cleanly. Try to avoid intricate designs that require precision beyond the laser's capabilities. If they are necessary, make sure to adjust the design for easier cutting.

Speed, Precision, and Material Compatibility

CNC laser cutting is faster than waterjet cutting, especially for thinner materials. It offers high precision, but waterjet cutting can handle thicker materials more easily. While laser cutting excels with metals and plastics, waterjet cutting is more versatile, working well with materials like stone, glass, and ceramics.

When to Use One Over the Other

Choose CNC laser cutting for projects that require fast, clean cuts in thinner metals and plastics. If you're working with thick materials or those prone to heat distortion, like certain metals, waterjet cutting may be the better option due to its cold-cutting nature.

Benefits and Limitations of Milling vs. Laser Cutting

CNC milling is great for creating complex 3D shapes and working with a wide variety of materials. However, it is generally slower and involves more tool wear. CNC laser cutting is faster, more precise, and perfect for cutting flat surfaces. Yet, it is limited to 2D cuts and struggles with thicker materials compared to milling.

Types of Cuts Best Suited for Each Technology

Laser cutting is ideal for detailed 2D cuts, like intricate patterns or designs in thin sheets of metal and plastic. Milling is better suited for making 3D shapes or machining parts that require both cutting and drilling.

Integration with AI and Machine Learning for Real-Time Optimization

CNC laser cutting is becoming smarter. AI and machine learning algorithms are being integrated into the systems to enable real-time optimization. This allows the machine to adjust cutting parameters like speed and power on the fly, improving efficiency and reducing errors.

Advances in Laser Power and Cutting Speed

Laser technology is constantly improving. Higher-powered lasers can now cut thicker materials more quickly, while faster cutting speeds help improve productivity. These advancements allow manufacturers to meet increasing demand for high-volume production with greater precision.

Trends in Automated and Interconnected Systems in CNC Machines

The future of CNC laser cutting is closely linked to automation. Machines are becoming more interconnected, allowing for seamless data exchange between different systems in a production line. This trend leads to greater efficiency, fewer errors, and more opportunities for remote monitoring and maintenance.

Material Type, Thickness, and Complexity of the Cut

The cost of CNC laser cutting can vary depending on the material being used. Metals are generally more expensive than non-metals like wood or acrylic. Additionally, thicker materials require more power and time to cut, which increases costs. The complexity of the cut also plays a role — intricate designs or tight tolerances take longer to process.

Machine Operation Time and Labor Costs

Machine operation time directly impacts the cost. The longer the machine runs, the higher the cost. Labor costs also factor in, especially if manual adjustments or post-processing is required.

Reducing Material Waste with Efficient Nesting

Nesting refers to how parts are arranged on the material to minimize waste. By optimizing the layout, you can reduce scrap material and save money. Software tools help design efficient nesting patterns for maximum material utilization.

Choosing the Right Type of CNC Laser Cutter for Your Needs

Choosing the right laser cutter can affect costs. For high-volume production, investing in a more efficient, higher-powered fiber laser cutter may reduce overall time and cost. However, for smaller jobs, a less powerful machine might be more cost-effective.

CNC laser cutting offers precise, fast, and efficient solutions for various industries. It's widely used for materials like metal, wood, and plastic. This technology helps improve production quality and reduce costs. As it continues to evolve, CNC laser cutting will play a larger role in modern manufacturing and design, offering even more innovative solutions.

A: CNC laser cutting offers precision with tolerances as tight as ±0.1mm, making it ideal for intricate and detailed cuts.

A: CNC laser cutting can cut thick metal, but efficiency decreases as the material gets thicker. High-powered lasers are needed for thicker metals, and cutting time increases.

A: Materials like copper, PVC, and polycarbonate should be avoided. Copper reflects the laser, while PVC and polycarbonate can emit harmful fumes or melt under the heat.