Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-05-13 Origin: Site

Mastering Laser Cutting: The Key to Flawless Results

Precision sheet metal fabrication demands more than just powerful equipment - it requires deep expertise in the laser cutting process. At Shandong Baokun Machinery Equipment Co.,ltd , we've perfected the art of turning raw materials into precision components through years of hands-on experience. Here's how we achieve consistently perfect cuts every time.

Precision sheet metal fabrication demands more than just powerful equipment - it requires deep expertise in the laser cutting process. At Shandong Baokun Machinery Equipment Co.,ltd , we've perfected the art of turning raw materials into precision components through years of hands-on experience. Here's how we achieve consistently perfect cuts every time.

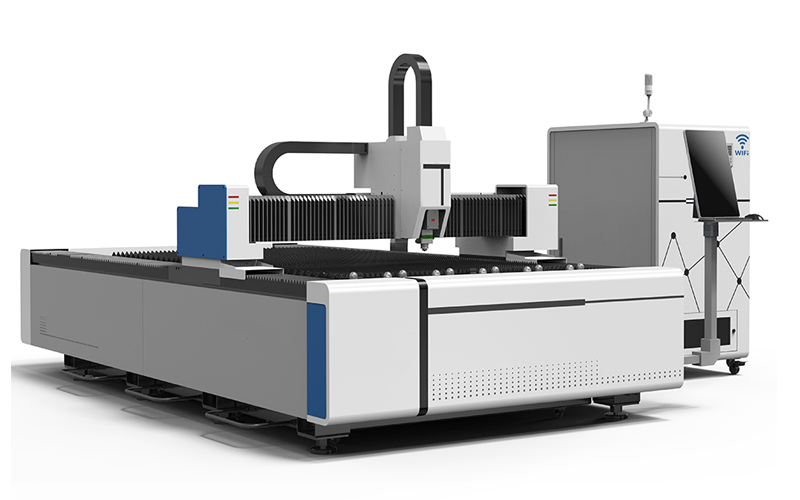

1. The Right Fiber Laser Cutting Machine Makes All the Difference

Our 6KW fiber laser cutters aren't just powerful - they're precision instruments that we've carefully calibrated. Different metals demand different approaches:

For stainless steel, we optimize nitrogen gas pressure to prevent oxidation

Carbon steel benefits from oxygen-assisted cutting at precise pressures

Aluminum requires specialized settings to prevent slag buildup

2. Our Engineers' Design Optimization Secrets of the fiber laser cutting machine

We've learned that perfect cutting starts long before the laser fires:

Vector files must be cleaned and optimized in our proprietary CAD system

Kerf compensation is adjusted for each material thickness

Nesting algorithms maximize material utilization without compromising cut quality

3. What Our Shop Floor Knows About the Fiber Laser Cutting Machine Maintenance

Daily laser maintenance isn't just a checklist - it's a ritual:

Lenses are cleaned with specialized optical-grade solutions every shift

Nozzle condition directly impacts edge quality - we inspect them hourly

Gas purity is verified before every major production run

4. Our Quality Assurance Process of the Fiber Laser Cutting Machine

We don't just cut - we certify every part:

First-off inspections verify every parameter before full production

Edge quality is measured under magnification

Weekly calibration ensures microns-level precision

Real-World Results:

Our recent architectural project required 5,000 identical stainless steel butterflies with interlocking tabs. Through meticulous process control, we held ±0.1mm tolerance across the entire production run - with zero secondary processing needed.

content is empty!

content is empty!