Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

Did you know metal laser cutting is revolutionizing industries with its precision?This process plays a crucial role in modern manufacturing, enabling faster and more accurate cuts. In this post, we’ll cover the definition, process, types of metal laser cutting, and the machines involved. You’ll also discover its advantages and real-world applications.

Laser cutting is a method where a focused high-power laser beam is used to cut materials, especially metals. Unlike traditional cutting techniques, the laser doesn’t physically touch the material. Instead, it uses concentrated light energy to melt, vaporize, or burn through the material, creating clean and precise cuts.

This technique stands out for its ability to cut intricate shapes and designs with extreme accuracy. The high-power laser beam is directed precisely onto the material, where it rapidly heats it to the point of cutting. This precision is far greater than conventional cutting methods.

High precision: Achieve cuts with accuracy as fine as 0.2mm, making it ideal for detailed work.

Speed and efficiency: Faster cutting times mean reduced operational costs.

Versatility: It can handle various metals such as steel, aluminum, and even alloys.

Clean cuts: The process results in smooth edges and minimal heat-affected zones, keeping the material’s integrity intact.

Laser Beam Generation:

A high-power laser is generated using a specialized light source. The laser creates a focused beam that concentrates energy on a single point, capable of reaching extremely high temperatures.

Beam Delivery and Focusing:

The laser beam travels through optics and a CNC system (Computer Numerical Control) to focus it precisely on the material. This focused beam ensures that the energy is applied exactly where it’s needed for cutting.

Cutting Action:

Once the beam reaches the material, it heats the metal to its melting or vaporization point. The intense heat melts or vaporizes the metal, depending on the cutting method and material type.

Motion Control:

The CNC system controls the movement of the laser beam or the material itself. This allows for intricate, precise cuts, following a pre-programmed path for complex designs.

Final Cut Quality:

The cutting process results in clean, smooth edges. The heat-affected zone (HAZ) is minimal, which reduces material waste and ensures high-quality cuts.

Nitrogen vs Oxygen in Assisting the Cutting Process:

Nitrogen and oxygen are commonly used in laser cutting, but each serves a different purpose. Nitrogen is often used for clean cutting, especially on materials like stainless steel. It helps prevent oxidation, ensuring smooth edges. Oxygen, on the other hand, is used in reactive cutting. It reacts with the material to create additional heat, speeding up the cutting process, especially on materials like carbon steel.

The Importance of High-Pressure Gases in Vaporization and Melting Cutting:

High-pressure gases play a crucial role in vaporization and melting cutting. They help remove the molten material from the cutting area, ensuring clean cuts. Oxygen is especially important in melting and reactive cutting, while nitrogen is more common in vaporization cutting. The pressure also helps maintain a high cutting speed and ensures minimal heat damage to the surrounding material.

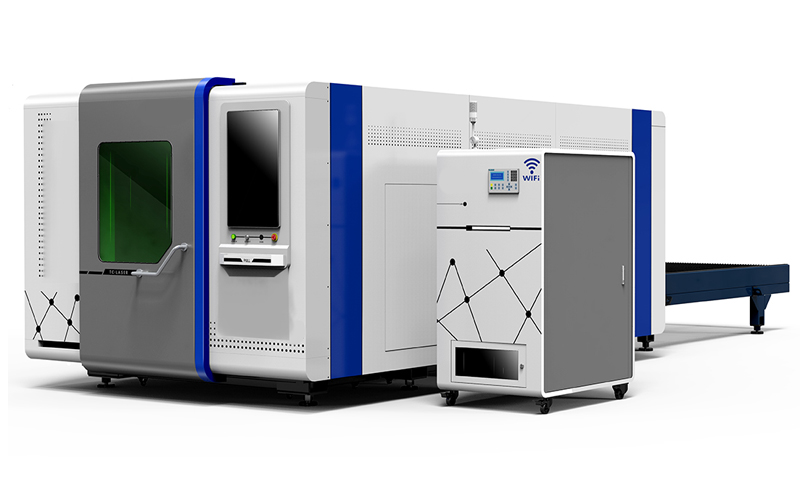

What are fiber laser cutters?

Fiber laser cutters use a solid-state laser technology, where the light is transmitted through optical fibers. This method delivers high precision and fast cutting speeds.

Advantages:

Speed: Faster cutting times due to high energy density.

Power efficiency: Fiber lasers use less energy for the same output.

Precision: Delivers extremely fine and accurate cuts.

Best materials for fiber laser cutting:

Ideal for cutting metals like stainless steel, aluminum, brass, and copper, especially for thin to medium thicknesses.

CO2 laser cutting technology and its applications:

CO2 lasers use a gas mixture, mainly CO2, to generate the laser beam. This type is widely used for both cutting and engraving various materials.

Pros and cons of CO2 lasers compared to fiber lasers:

Pros: Can cut thicker materials and is more versatile in cutting non-metals like wood, acrylic, and plastic.

Cons: Less efficient in cutting metals compared to fiber lasers, and typically slower.

How crystal laser machines work:

These machines use crystal lasers, typically Nd:YAG or Nd:YVO lasers, which are solid-state lasers. The crystals are doped with elements like neodymium to create the laser beam.

Common applications of crystal laser cutters:

Best for cutting metals like stainless steel and aluminum, especially in applications requiring high precision, such as aerospace and medical industries.

What are direct diode lasers?

Direct diode lasers generate light directly from semiconductor junctions. They’re increasingly used in industrial laser cutting for their simplicity and cost-effectiveness.

Their increasing role in laser cutting due to low maintenance and durability:

Direct diode lasers are known for their long lifespan and minimal maintenance needs, making them an attractive option for industries with high-volume production.

How vaporization cutting works:

This technique uses a high-powered laser to heat the material to its boiling point. The material then vaporizes and is blown away by a gas jet, creating a clean cut.

Materials best suited for this technique:

Ideal for cutting very thin metals and non-metals like paper, plastics, and rubber.

Description of melting cutting:

The laser melts the material, and the molten metal is blown away by an assist gas, leaving a clean, precise edge.

Key materials and metals used in this process:

Works well with metals like stainless steel, aluminum, and titanium, particularly when the material is non-oxidizing.

How oxygen cutting works and the exothermic reaction:

In this method, a laser heats the material, and oxygen is used as the cutting gas. The reaction generates additional heat, speeding up the cutting process.

Materials like carbon steel suitable for this process:

Oxygen cutting is most commonly used for carbon steel and other metals that react with oxygen to create a rapid cutting effect.

The process of scribing and how controlled fractures are created:

A high-energy laser creates a small groove in the material, and pressure is applied to fracture the material along the scribed line.

When and why scribing is used in manufacturing:

Scribing is often used for brittle materials or when creating precise cracks for further processing, such as in glass and ceramics.

Tolerance levels of metal laser cutting:

Metal laser cutting offers exceptional precision, achieving tolerances as tight as 0.2mm. This makes it ideal for intricate designs and complex shapes.

Importance of accuracy in industrial manufacturing:

In industries like aerospace and automotive, accuracy is crucial. Laser cutting ensures high-quality results, reducing the need for post-processing and rework.

How metal laser cutting increases production speed:

Laser cutting significantly reduces processing times, especially for high-volume production. It’s faster than traditional methods like plasma or water jet cutting.

The benefits of quick cuts and low operational downtime:

Faster cutting speeds result in fewer interruptions, increasing overall productivity and lowering costs for businesses.

How laser cutting minimizes scrap material:

The precision of laser cutting means that it generates less scrap material, optimizing material usage. This results in reduced waste during manufacturing.

The environmental and cost benefits of reducing waste:

Less scrap material means fewer resources are wasted, lowering the environmental impact and reducing material costs.

Laser cutting ability to work with a wide range of materials:

It can cut metals like stainless steel, aluminum, and titanium, as well as non-metal materials such as plastics and wood.

Thick metals vs thin metals in laser cutting applications:

Laser cutting can handle both thick and thin metals effectively. Thinner materials can be cut faster, while thicker materials require more power for efficient cutting.

How metal laser cutting is used for aerospace components:

In aerospace, metal laser cutting is crucial for manufacturing high-precision components like turbine blades, wing structures, and engine parts.

Importance of precision in aircraft manufacturing:

Aircraft components must meet strict tolerances. Laser cutting ensures the accuracy required for safety and performance standards.

Applications of laser cutting in producing automobile parts:

Laser cutting is widely used to create parts such as chassis components, exhaust systems, and body panels.

How laser cutting improves design flexibility in the automotive sector:

Laser cutting allows for intricate designs and adjustments, enhancing the flexibility in producing parts with complex shapes.

Use of laser cutting in electronics manufacturing:

Laser cutting is used to create precise metal connectors, housings, and components for electronic devices.

Metal fabrication: How laser cutting enhances precision:

In metal fabrication, it ensures high-quality, precise cuts, reducing waste and improving the final product’s quality.

How metal laser cutting helps in the production of medical equipment:

Laser cutting is used for parts like surgical instruments, implants, and diagnostic equipment. It ensures high-quality, sterile cuts.

High standards of clean cuts for medical parts:

For medical applications, laser cutting provides clean edges and minimal thermal effects, crucial for maintaining safety and hygiene standards.

Material Compatibility:

Different materials require different cutting technologies. Some machines work better on metals like steel and aluminum, while others may be more suited to non-metal materials like plastics or wood.

Laser Power:

Laser power is crucial in determining the thickness of materials you can cut. Higher power is needed for thicker materials, while lower power works better for thinner ones.

Precision Requirements:

If your projects demand tight tolerances, you need a machine known for its high accuracy. Machines like fiber lasers are ideal for precision cutting, especially for intricate designs.

Key differences and advantages of fiber lasers over CO2 lasers:

Fiber lasers are known for their speed, energy efficiency, and precision, especially on metals like stainless steel. They are faster and consume less energy than CO2 lasers.

CO2 lasers, on the other hand, are more versatile and can cut both metals and non-metals like wood and acrylic, but they tend to be slower and less energy-efficient than fiber lasers.

Which one is more suitable for your business needs?

If you primarily work with metals and need high speed and precision, fiber lasers are the better choice. For businesses needing to cut a variety of materials, including non-metals, CO2 lasers might be more suitable.

The importance of CNC systems in controlling laser cutting:

CNC (Computer Numerical Control) systems guide the laser cutter to follow a precise path, ensuring accuracy. This is essential for intricate designs and complex cuts.

How CNC systems improve cutting precision and efficiency:

CNC systems enhance cutting precision by automating the process, reducing human error. They also increase efficiency by ensuring faster, consistent cuts across multiple pieces of material.

The future of fiber laser cutting technology:

The next generation of fiber lasers will feature higher power outputs and improved beam quality. This allows for cutting thicker materials faster and with more precision.

How higher-powered fiber lasers are changing the industry:

Higher-powered lasers are opening up new possibilities for industries like aerospace and automotive, enabling faster processing times and more complex cuts on thicker materials.

The impact of automation and AI on laser cutting:

Automation and AI are streamlining the cutting process. These technologies help optimize machine settings, detect problems early, and improve overall efficiency.

How smart manufacturing is optimizing the cutting process:

Smart manufacturing uses connected systems to monitor and adjust the cutting process in real-time, making it faster, more reliable, and cost-effective.

Emerging industries and applications for metal laser cutting:

Industries like biotechnology, additive manufacturing, and renewable energy are discovering new ways to incorporate metal laser cutting. From cutting parts for medical devices to creating components for solar panels, the future holds many new opportunities.

Metal laser cutting is a game-changer in modern manufacturing, offering precision, speed, and versatility.

Investing in laser cutting technology allows businesses to improve efficiency, reduce waste, and stay competitive in industries like aerospace, automotive, and electronics.

A: Laser cutting can handle a wide range of materials, including metals like stainless steel, aluminum, titanium, and non-metals like plastics, wood, and ceramics.

A: Fiber lasers are faster, more energy-efficient, and better for cutting metals, while CO2 lasers are more versatile, handling both metals and non-metals.

A: Yes, laser cutting can handle thick metals, especially with higher-powered fiber lasers, though cutting thick metals takes longer.

A: Metal laser cutting is highly accurate, with tolerances as tight as 0.2mm, making it ideal for precise parts.

A: Industries like aerospace, automotive, electronics, medical devices, and metal fabrication commonly use metal laser cutting for precision parts.

A: The cost of a metal laser cutting machine varies based on its power and features, ranging from $20,000 to $500,000.