Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

Fiber lasers have transformed metal cutting with precision and speed. But how thick can they cut?In this post, we’ll explore the capabilities of fiber lasers, including the maximum thickness they can handle for different materials. Understanding this is key when selecting the right laser for your needs.

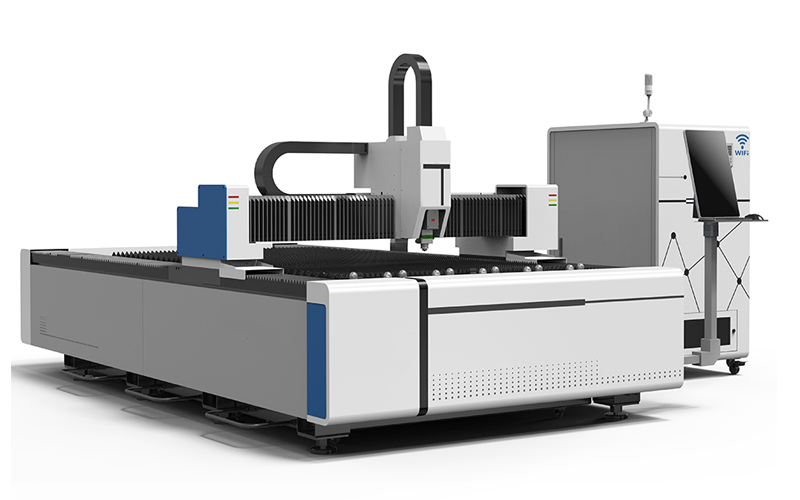

A fiber laser cutter is a machine that uses a high-powered laser to cut through materials like metals with precision. It works by focusing a laser beam onto the material’s surface, melting or vaporizing it to create clean cuts. Unlike traditional cutting methods, fiber lasers offer exceptional accuracy, speed, and efficiency.

Fiber lasers use a solid-state laser, transmitting the light through optical fibers. This setup is what sets them apart from other laser types. The light is focused on the material, where it melts, vaporizes, or burns through it, depending on the material and the laser settings.

Fiber lasers have a few advantages over CO2 lasers and plasma cutters:

Efficiency: Fiber lasers are more energy-efficient. They waste less power in the cutting process.

Speed: Fiber lasers cut faster than CO2 lasers, especially with thin materials.

Precision: They offer higher accuracy and cleaner cuts compared to plasma cutters, which often create rough edges.

Material Handling: Fiber lasers can handle reflective materials like aluminum and copper better than CO2 lasers.

| Feature | Fiber Lasers | CO2 Lasers | Plasma Cutters |

|---|---|---|---|

| Speed | High | Moderate | Low |

| Efficiency | High | Moderate | Low |

| Precision | High | Moderate | Low |

| Material Flexibility | High | Moderate | Low |

Several factors determine how thick a material can be cut by a fiber laser. These include the laser power, the material type, the assistive gases used, and the cutting speed and accuracy. Let’s break each of these down:

The power of the fiber laser is one of the most crucial factors. Higher power allows the laser to cut through thicker materials. For example, a 1000W laser is suitable for thin materials, while lasers above 6000W can handle thicker steel or even 100mm+ material. More power results in faster cuts and cleaner edges, especially when cutting thicker pieces.

Different materials react differently to the laser beam, which affects the cutting thickness. Some materials are easier to cut than others, meaning they can handle more thickness.

Steel: Can be cut up to 60mm with high-powered lasers.

Stainless Steel: Fiber lasers can cut up to 50mm of stainless steel with the right setup.

Aluminum: Due to its reflectivity, aluminum can only be cut up to around 10mm efficiently.

Copper: Requires higher power lasers for cuts, typically up to 12mm, due to its reflective nature.

Assist gases play a significant role in the cutting process. They can affect the cutting speed, quality, and even the maximum thickness:

Nitrogen (N₂): Used for clean cuts, especially in stainless steel and aluminum. It helps reduce oxidation and improve edge quality.

Oxygen (O₂): Commonly used for carbon steel. Oxygen speeds up the cutting process, especially for thicker materials, but can cause oxidation on the edges.

Air: A cost-effective option for thinner materials, but less suitable for cutting thicker materials.

The speed at which the laser cuts also impacts how thick the material can be. While faster cutting speeds are ideal for thin materials, slower speeds are necessary for thicker materials to ensure clean and precise cuts. Slower speeds allow the laser to focus longer on the material, resulting in a deeper cut. However, cutting too slowly can also result in heat buildup, which may negatively affect the quality.

| Factor | Impact on Thickness | Material Example |

|---|---|---|

| Laser Power | Higher power = thicker cuts | Steel, Stainless Steel |

| Material Type | Different materials, different limits | Aluminum (10mm max), Steel (60mm max) |

| Assist Gases | Nitrogen = cleaner cuts, Oxygen = faster cutting | Nitrogen (stainless steel), Oxygen (carbon steel) |

| Cutting Speed | Slower for thicker cuts | All materials |

Fiber lasers are capable of cutting a variety of materials, but the maximum thickness they can handle depends on several factors, including laser power, material type, and cutting speed. Let’s take a closer look at how fiber lasers perform with different materials.

Carbon steel is one of the most common materials for fiber laser cutting, and the thickness it can handle varies based on the laser power.

Low Power Lasers (1000W - 4000W):

Can cut up to 20mm thickness.

Speed: For 1mm carbon steel, the cutting speed is around 12-15 meters per minute (m/min).

Speed decreases as the material gets thicker.

High Power Lasers (6000W - 30000W):

Can cut up to 70mm thickness.

Speed: At 10mm, cutting speeds can range from 2.5-3.5 m/min, with oxygen as the assist gas to speed up the process.

Extra-High Power Lasers (40000W - 60000W):

Can handle thicknesses of up to 100mm or more.

Speed: At 20mm thickness, cutting speeds range from 3.0-4.0 m/min, with nitrogen or a mix of gases used for better results.

Stainless steel is more difficult to cut due to its reflective properties, but fiber lasers can still cut through it with the right power settings.

Low Power Lasers:

Can cut up to 10mm thickness.

Speed: Cutting 1mm stainless steel can be done at speeds up to 15 m/min with nitrogen for clean cuts.

High Power Lasers:

Can cut up to 30mm thickness.

Speed: For 3mm stainless steel, cutting speeds are typically around 2.5-4.0 m/min with nitrogen, ensuring clean edges.

Aluminum and other reflective metals like copper are more challenging for fiber lasers, but they can still be cut with proper settings.

Aluminum:

Can be cut up to 10mm thickness.

Due to high reflectivity, aluminum requires a higher power laser, typically around 4000W to 6000W, and nitrogen is usually preferred as the assist gas to minimize oxidation and achieve clean cuts.

Copper and Brass:

Fiber lasers can cut up to 12mm of copper.

Like aluminum, these metals are reflective, requiring lasers with higher power to handle thicker cuts.

| Material | Laser Power | Max Thickness | Cutting Speed (m/min) | Assist Gas |

|---|---|---|---|---|

| Carbon Steel | 1000W - 4000W | Up to 20mm | 12-15 (1mm thickness) | Oxygen |

| 6000W - 30000W | Up to 70mm | 2.5-3.5 (10mm thickness) | Oxygen | |

| 40000W - 60000W | 100mm+ | 3.0-4.0 (20mm thickness) | Nitrogen | |

| Stainless Steel | Low Power | Up to 10mm | 15 (1mm thickness) | Nitrogen |

| High Power | Up to 30mm | 2.5-4.0 (3mm thickness) | Nitrogen | |

| Aluminum | 4000W - 6000W | Up to 10mm | 4-5 (1mm thickness) | Nitrogen |

| Copper/Brass | 6000W - 12000W | Up to 12mm | 3-4 (1mm thickness) | Nitrogen |

Laser power is one of the most important factors influencing the maximum thickness a fiber laser can cut. As laser wattage increases, so does the cutting capacity, allowing the laser to cut through thicker materials more efficiently. Here's how different power levels impact cutting thickness:

Suitable for thin materials: This power range is ideal for cutting materials like thin steel or stainless steel.

Maximum thickness: Typically cuts up to 20mm thickness.

Speed: At 1mm thickness, it can cut at speeds of 12-15 m/min.

Best for: Light industries like signage, automotive parts, and small-scale metal fabrication.

Handles moderate thickness: This range is best for cutting materials up to 70mm thick.

Maximum thickness: Can handle materials like medium carbon steel or stainless steel.

Speed: Cutting 10mm thickness at around 2.5-3.5 m/min.

Best for: Manufacturing heavy-duty parts for machinery, construction, and industrial equipment.

Cuts thick industrial materials: High-powered lasers are designed for thicker materials like 70mm to 100mm carbon steel.

Maximum thickness: Cuts up to 100mm or more.

Speed: For 20mm thickness, cutting speeds range from 3.0-4.0 m/min.

Best for: Aerospace, shipbuilding, and heavy-duty industrial projects.

Ideal for very thick materials: With power levels over 40000W, lasers can cut through extremely thick materials up to 100mm+.

Maximum thickness: Suitable for cutting large, structural steel pieces, or metal plates thicker than 100mm.

Speed: At 30mm thickness, it cuts at speeds of 2.4-3.0 m/min.

Best for: Structural steel fabrication, large-scale manufacturing, and construction.

| Laser Power Range | Suitable Thickness | Speed Range (m/min) | Ideal Applications |

|---|---|---|---|

| 1000W - 4000W | Up to 20mm | 12-15 (1mm thickness) | Light industries, signage |

| 6000W - 12000W | Up to 70mm | 2.5-3.5 (10mm thickness) | Heavy-duty parts, machinery |

| 15000W - 30000W | Up to 100mm | 3.0-4.0 (20mm thickness) | Aerospace, shipbuilding |

| 40000W and beyond | 100mm+ | 2.4-3.0 (30mm thickness) | Structural steel fabrication |

Selecting the right fiber laser depends on the material you're cutting and its thickness. Different metals have unique properties that require specific considerations. Let's explore how to choose the appropriate laser for various materials.

Typical Thicknesses: Carbon steel is one of the easiest metals to cut. Fiber lasers can cut up to 100mm thickness, depending on the laser power.

Considerations: Use higher-powered lasers (6000W+) for thicker steel to ensure clean and accurate cuts. Oxygen as an assist gas can speed up the process and improve efficiency.

Best Laser Power: For cutting up to 70mm, a 6000W-15000W laser is ideal.

Challenges: Stainless steel is reflective and can cause issues with lasers, especially at thicker gauges. Cutting 20mm+ requires careful settings to avoid oxidation and achieve a clean edge.

Solutions: Use nitrogen as the assist gas to minimize oxidation and improve edge quality. Higher power lasers (6000W+) are needed for better efficiency and precision when cutting thicker stainless steel.

Best Laser Power: For up to 30mm thickness, 6000W-12000W lasers work best.

Special Considerations: Aluminum is highly reflective, which can cause issues with laser absorption. It requires more power to achieve a clean cut, especially as the thickness increases.

Challenges: Laser settings must be adjusted to avoid heat buildup and maintain edge quality. Nitrogen is the preferred assist gas for aluminum cutting.

Best Laser Power: A laser power of 4000W-6000W is suitable for cutting up to 10mm of aluminum.

Difficulty: Copper and brass are also reflective metals, making them harder to cut. A higher laser power is needed to manage these materials effectively.

Required Laser Specifications: For efficient cutting, copper and brass typically require lasers above 6000W, along with nitrogen or oxygen to ensure proper cutting and minimize edge imperfections.

Best Laser Power: For up to 12mm of copper and brass, a 6000W+ laser with nitrogen assist gas works best.

| Material | Maximum Thickness | Laser Power Needed | Best Assist Gas | Considerations |

|---|---|---|---|---|

| Carbon Steel | 100mm | 6000W - 30000W | Oxygen | Higher power for thicker cuts |

| Stainless Steel | 30mm | 6000W - 12000W | Nitrogen | Nitrogen to prevent oxidation |

| Aluminum | 10mm | 4000W - 6000W | Nitrogen | Reflectivity requires high power |

| Copper/Brass | 12mm | 6000W+ | Nitrogen/Oxygen | Higher power to handle reflectivity |

Fiber lasers are commonly used in industries that require cutting thick materials. Their ability to cut through large, thick pieces of metal makes them ideal for high-demand applications such as shipbuilding, aerospace, and construction. Here’s a look at how fiber lasers are used in these sectors and some case studies showing their impact.

Shipbuilding: Fiber lasers can cut through thick steel plates used in shipbuilding. These materials often exceed 100mm, requiring high-powered lasers (up to 60000W) for precision and speed.

Aerospace: The aerospace industry uses fiber lasers to cut thick titanium and aluminum alloys, often in the range of 30mm to 50mm. High precision is essential for these critical applications, where accuracy and minimal heat distortion are required.

Construction: Fiber lasers are used in cutting thick structural steel beams for construction projects. These materials can range from 50mm to over 100mm, demanding powerful laser systems for efficient processing.

Shipbuilding Industry

Challenge: Cutting through thick steel plates up to 100mm.

Solution: Using 30000W fiber lasers, shipbuilders can achieve high cutting speeds and precision without causing excessive heat damage.

Outcome: Faster production times and improved quality control, reducing material waste and labor costs.

Aerospace Sector

Challenge: Cutting titanium and other alloys with high accuracy and minimal thermal distortion.

Solution: High-power fiber lasers (12000W+) are used to achieve the necessary cut quality for aerospace components.

Outcome: The aerospace industry benefits from lightweight, durable parts with minimal post-processing required.

Construction Industry

Challenge: Cutting large structural beams up to 100mm.

Solution: Construction companies use fiber lasers in a variety of beam thicknesses. The lasers efficiently cut through thick steel while maintaining precision.

Outcome: Significant savings in time and material, especially in the fabrication of pre-cut pieces for faster assembly.

| Industry | Material Type | Maximum Thickness | Laser Power | Applications |

|---|---|---|---|---|

| Shipbuilding | Steel plates | Up to 100mm | 30000W | Ship hulls, large metal structures |

| Aerospace | Titanium, Alloys | 30mm - 50mm | 12000W+ | Aircraft parts, engine components |

| Construction | Structural steel | 50mm - 100mm | 15000W - 30000W | Steel beams, framework fabrication |

Assistive gases play a crucial role in the fiber laser cutting process. They influence the cutting quality, speed, and material thickness. Different gases are used depending on the material being cut. Let’s explore how nitrogen, oxygen, and air affect cutting performance.

Usage: Nitrogen is commonly used for cutting stainless steel and aluminum.

Impact: It helps achieve clean cuts by preventing oxidation and reducing discoloration, especially in stainless steel.

Effect on Thickness: Nitrogen allows for smooth edges and higher-quality cuts in thinner materials. For thicker stainless steel, nitrogen helps maintain precision and reduces the need for post-processing.

Best for: Stainless steel, aluminum, and other metals where clean cuts are a priority.

Usage: Oxygen is ideal for cutting carbon steel.

Impact: It enhances the cutting speed and thickness. When oxygen is used, it reacts with the material, creating an exothermic reaction that helps accelerate the cutting process.

Effect on Thickness: Oxygen allows fiber lasers to cut through thicker carbon steel, typically up to 60mm or more.

Best for: Carbon steel and other materials where speed is important, though it can cause oxidation on the edges.

Usage: Air is the most cost-effective assistive gas for cutting thinner materials.

Impact: It provides a basic cutting process but is less effective for thicker materials compared to nitrogen or oxygen.

Effect on Thickness: Air is suitable for thin metals (up to 5mm) but has limitations when it comes to cutting thicker materials. It results in slightly rougher edges compared to nitrogen or oxygen.

Best for: Thin materials, where cost-efficiency is important.

| Assistive Gas | Best For | Thickness Impact | Speed Impact | Quality Impact |

|---|---|---|---|---|

| Nitrogen | Stainless Steel, Aluminum | Clean cuts, thinner materials | Slower than oxygen | Smooth edges, high quality |

| Oxygen | Carbon Steel | Thick cuts (up to 60mm) | Speeds up cutting | Oxidation on edges |

| Air | Thin Materials | Limited to 5mm thickness | Moderate speed | Rougher edges, less clean |

While fiber lasers are powerful tools for cutting a variety of materials, they come with certain challenges, especially when dealing with thick materials. These challenges can affect cutting performance and quality. Let’s explore some common issues and how to overcome them.

Beam Quality: As the material thickness increases, maintaining a focused, high-quality beam becomes difficult. Any variation in beam quality can result in uneven cuts or poor edge quality.

Solution: Regularly calibrate the laser and ensure the optical components are clean and well-maintained. High-powered lasers also benefit from advanced beam-shaping technology to maintain consistency.

Cutting Speed: Thicker materials require slower cutting speeds to ensure precision and reduce heat buildup. If the speed is too high, the laser may not cut deeply enough, resulting in incomplete cuts or poor quality.

Solution: Adjust cutting speeds based on material thickness. Slower speeds for thicker materials ensure deep, precise cuts while maintaining high quality.

Material Behavior: Different materials react differently to the laser. For example, metals like aluminum reflect much of the laser energy, making them harder to cut. Other metals, like carbon steel, may cause more heat buildup, which can affect the cut.

Solution: Choose the right assistive gas, and adjust laser power settings to accommodate each material’s unique behavior. Nitrogen is ideal for reflective metals, while oxygen works better for carbon steel.

Laser Power Setup: Use a higher-powered laser for thicker materials. For instance, a 6000W or more powerful laser is necessary for cutting materials thicker than 20mm. This ensures that the laser can penetrate the material effectively.

Tip: Always match laser power to the material thickness to avoid overuse or underuse of energy.

Proper Maintenance: Regular maintenance of the fiber laser is critical. This includes cleaning the optics, checking alignment, and ensuring the cooling system is functioning properly.

Tip: Implement a maintenance schedule to prevent performance degradation, which can result in poor cutting quality.

| Challenge | Impact on Cutting | Solution |

|---|---|---|

| Beam Quality | Uneven cuts, poor edges | Regular calibration, clean optics |

| Cutting Speed | Incomplete cuts, rough edges | Adjust speed for material thickness |

| Material Behavior | Heat buildup, poor precision | Use right gas and adjust power settings |

| Laser Power | Inability to cut thick materials | Use high-powered lasers for thick cuts |

Fiber lasers offer impressive cutting capabilities, but it's essential to weigh the cost against performance. Let’s break down when investing in a higher-powered laser is worthwhile and how fiber lasers compare to traditional cutting methods in terms of efficiency.

Higher-Powered Lasers for Thicker Materials: Investing in a higher-powered fiber laser is necessary for cutting thicker materials effectively. If your projects involve materials over 20mm thick, a laser with power ranging from 6000W to 30000W will deliver the speed and precision needed for efficient cutting.

When to Invest: If your cutting needs demand precision in high-thickness materials regularly, it’s worth the extra investment. The increased cutting speed and reduced need for post-processing justify the higher cost in the long run.

Lower-Powered Lasers: For thinner materials (up to 10mm), a laser in the 1000W to 4000W range may be sufficient. This is more cost-effective for businesses that mainly work with smaller projects.

Cost Efficiency: Lower-powered lasers can handle lighter workloads without the higher upfront costs, making them ideal for smaller operations or businesses just starting.

Energy Consumption: Fiber lasers are known for their energy efficiency compared to traditional cutting methods. They require less power for the same or even better results. For example, a 6000W fiber laser uses less energy than a CO2 laser of the same power output, reducing operational costs.

Comparison: Fiber lasers consume significantly less energy than plasma cutters and CO2 lasers, especially during long cutting sessions. This makes fiber lasers a more sustainable option for industrial-scale operations.

Maintenance: Fiber lasers are low-maintenance compared to other types of lasers. Unlike CO2 lasers, fiber lasers don’t require regular replacement of consumables like mirrors or lenses. This lowers ongoing maintenance costs and reduces downtime.

Durability: Fiber lasers have a longer lifespan due to fewer moving parts, resulting in fewer repairs over time and more consistent performance.

Operational Costs: While fiber lasers may have a higher initial cost, their long-term operational savings are substantial. The reduced energy consumption and low maintenance costs lead to a lower total cost of ownership over time.

Cost Comparison: When you factor in the efficiency, lower maintenance, and speed, fiber lasers offer a better return on investment (ROI) compared to older cutting technologies.

| Laser Power Range | Initial Cost | Energy Efficiency | Maintenance Costs | Best For |

|---|---|---|---|---|

| 1000W - 4000W | Low | High | Low | Thin materials, small businesses |

| 6000W - 12000W | Moderate | High | Moderate | Medium-thickness materials |

| 15000W - 30000W | High | Moderate | Low | Thick industrial materials |

| 40000W - 60000W | Very High | Moderate | Low | Large-scale manufacturing |

Operating high-power fiber lasers to cut thick materials requires strict safety precautions. The intense energy of these lasers can pose serious risks to both operators and equipment. Let’s discuss the safety measures that should be in place when using these powerful machines.

Laser Radiation: High-power fiber lasers emit intense laser radiation, which can be harmful to the eyes and skin. Always ensure that operators are fully aware of the risks and the necessary safety protocols.

Solution: Use laser enclosures and protective barriers to contain the laser beam. These barriers should be made of materials that absorb or reflect the laser radiation.

Heat and Fire Hazards: Cutting thick materials generates heat, and sparks can fly off the material. These sparks can ignite nearby combustible materials.

Solution: Install fire-resistant shields around the cutting area and ensure the cutting environment is free from flammable materials.

Fume and Gas Exposure: Cutting thick materials, especially metals like steel, produces fumes and gases that can be harmful to health. Some materials may release toxic gases when cut, such as zinc fumes from galvanized steel.

Solution: Use proper ventilation systems and fume extraction units. Ensure that the workspace is equipped with air filtration systems to protect workers.

Protective Eyewear: Operators must wear high-quality laser safety goggles that protect against the specific wavelength of the laser being used.

Tip: Make sure the eyewear complies with ANSI Z136.1 standards for laser safety.

Flame-Retardant Clothing: Since sparks and molten metal may be produced during cutting, operators should wear flame-retardant clothing to protect against burns.

Tip: Avoid wearing synthetic clothing, which can catch fire easily. Opt for cotton or specialized flame-resistant fabrics.

Safety Training and Procedures: Operators should receive comprehensive training on the safe operation of fiber lasers, especially for thick material cuts. This includes understanding machine settings, emergency shut-off procedures, and proper maintenance practices.

Tip: Conduct regular safety drills and keep safety manuals readily available for quick reference.

| Safety Measure | Purpose | Example Equipment | Best Practice |

|---|---|---|---|

| Laser Enclosures | Contain laser radiation | Protective barriers | Always use for high-power lasers |

| Fire-Resistant Shields | Protect from sparks and heat | Flame-resistant barriers | Place around the cutting area |

| Fume Extraction Systems | Vent harmful fumes and gases | Industrial air filtration | Use when cutting metals like steel |

| Protective Eyewear | Protect eyes from laser radiation | Laser safety goggles | Ensure proper fit and ANSI certification |

| Flame-Retardant Clothing | Protect skin from sparks and heat | Flame-resistant clothing | Always wear during operation |

Fiber lasers can cut materials up to 100mm thick, depending on the laser power and material type. Higher-powered lasers (6000W+) are ideal for thicker materials. Factors like assistive gases, cutting speed, and beam quality affect cutting performance.

When choosing a fiber laser, consider your specific needs based on material thickness, speed, and quality requirements.

A: A 1500W fiber laser can typically cut up to 6mm of carbon steel or 3mm of stainless steel, depending on the material and gas used.

A: Nitrogen is ideal for cutting stainless steel as it prevents oxidation and ensures clean edges. Oxygen can be used for faster cuts in carbon steel but isn't suitable for stainless steel.

A: Yes, fiber lasers can cut aluminum, brass, and other reflective metals, but they need specific settings and gases (usually nitrogen) for effective cutting.

A: At 3000W, a fiber laser can cut 10mm carbon steel at speeds of 2.0 to 5.0 meters per minute, depending on the gas used.

A: Yes, fiber lasers are eco-friendly compared to traditional methods. They require fewer consumables and generate less waste, reducing environmental impact.